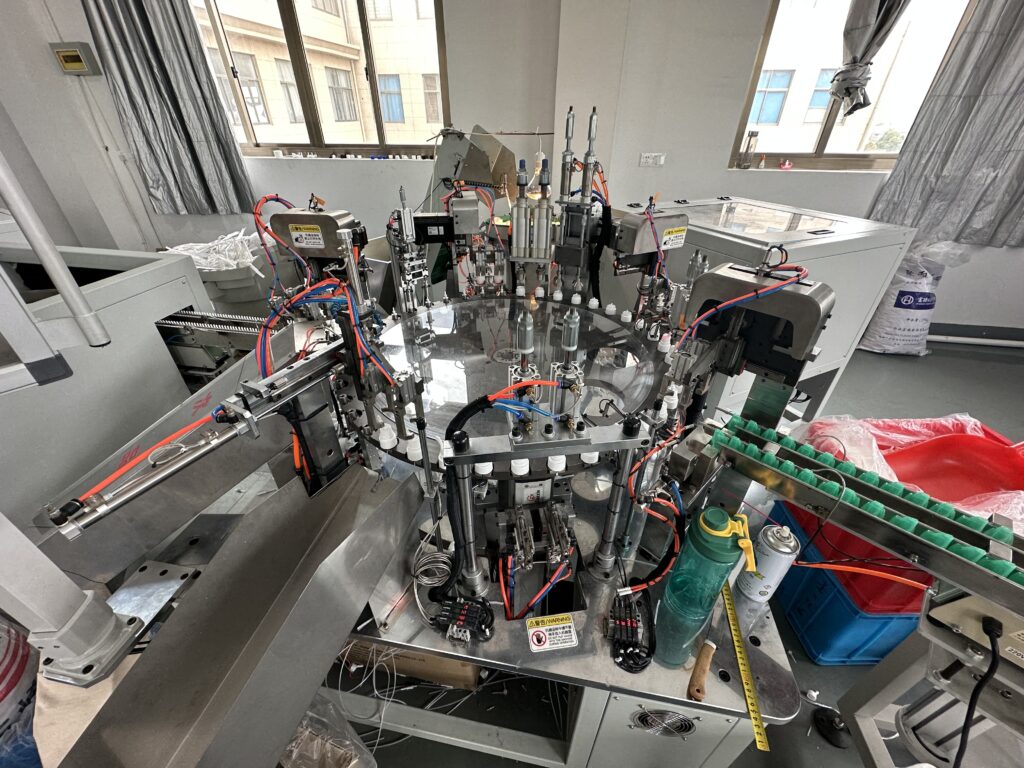

Dili lang kami maghimo mga butang nga plastik nga pakete, apan nagdisenyo usab kami ug naghimo usab nga mga makina nga manapusing nga pakete sa plasticing. Sa pagkakaron, Ang kompanya sa panguna nagpalambo ug naghimo sa awtomatikong kagamitan sa asembliya alang sa adlaw-adlaw nga mga butang nga kemikal sama sa mga pusil nga plastik nga square, mga bomba sa lotion, gagmay nga mga sprays, ug uban pa. Ang makinarya kay naglihok. Stable, paspas, ubos nga kasaba, maayo kaayo nga katukma, uban sa a 99.9% rate sa ani. Kini episyente ug lig-on, sayon gamiton ug mamentinar, ug naghiusa sa asembliya ug pagsulay. Ang gipahiangay nga mga disenyo mahimo’g himuon aron matagbaw ang mga kostumer’ asembliya kinahanglan alang sa lain-laing mga produkto ug pagpakunhod sa gidaghanon sa mga kawani sa asembliya alang sa mga kustomer. Makapamenos usab kini pag-ayo sa gasto sa produksyon sa produkto, nagtugot sa mga kustomer sa pagdugang sa ganansya ug potensyal sa merkado.

Ang usa ka awtomatik nga tig-assisa nga makina usa ka matang sa episyente nga kagamitan sa mekanikal nga gigamit ang daghang mga sensor, aktuator, ug mga sistema sa pagkontrol aron matuman ang awtomatiko nga asembliya sa produkto pinaagi sa teknolohiya sa programming ug automation. Ang paggamit sa mga awtomatikong mga makina sa asembliya sa modernong produksiyon nagkadaghan, nagtanyag hinungdanon nga mga benepisyo ug pag-ayo.

Ang mga gimbuhaton ug mga buluhaton sa awtomatik nga makina sa assembly mao ang mga musunud:

1.Ang sistema sa conveyor ang nagdumala sa mga nag-uswag nga mga produkto gikan sa usa ka workstation hangtod sa sunod. Aron makab-ot ang high-speed ug pagbalhin sa produkto sa katukma, Ang sistema sa transmission kanunay naggamit sa mga sinturon sa conveyor, rampa, o robotic Arms.

2.Ang usa ka sistema sa pag-ila sa produkto gigamit aron mahibal-an ang mga kinaiya ug lokasyon. Ang sistema sa pag-ila nagpaila sa logo o mga bahin sa produkto gamit ang pagproseso sa imahe, Mga Sensor sa Photoelectric, o pag-scan sa barcode alang sa sunud nga pagproseso ug panagtigum.

3.Ang sistema sa clamping ug pagtigum mao ang kasingkasing sa asembleya sa asembleya. Kini ang nagdumala sa pag-uban sa lainlaing mga piraso aron mahimo ang katapusan nga sangputanan. Ang mga sistema sa pag-clamping ug pagtigum sagad nga adunay robotic arm, mga fixtures, ug mga himan, Lakip sa ubang mga sangkap, nga nagpundok sa mga bahin sa piho nga mga posisyon nga lakang pinaagi sa lakang gamit ang tukma nga pagpugong sa posisyon ug pagpilit sa pagpilit.

4.Ang sistema sa pagpugong mao ang utok sa asembleya sa asembleya, ug kini ang nagdumala sa pagpugong sa kompleto nga pag-abut sa makina sa asembleya. Plac (Programmable logic controller) o ang mga sistema sa pagkontrol sa kompyuter nga nakabase sa computer mahimong ma-program ug ipadapat. Mahimo nga bantayan ang kahimtang sa operasyon sa matag aytem sa tinuud nga oras ug awtomatik nga magbag-o ug makontrol kini base sa mga parameter ug mga lagda nga gipasabut sa katukma ug kalig-on sa mga lagda.

5.Atol sa proseso sa asembleya, Ang sistema sa pagrekord sa datos ug pag-analisar nagkolekta ug nag-analisar sa datos. Ang sistema sa pagrekord ug pag-analisar sa datus mahimong magtala sa lainlaing mga parameter ug mga timailhan sa panahon sa operasyon sa makina sa asembleya, sama sa temperatura, kapit-os, kakusog, ug uban pa, gamit ang mga sensor ug pag-monitor sa kagamitan. Kini nga mga datos mahimong magamit aron ma-optimize ug mapaayo ang proseso sa paghimo, busa ang pagdugang sa kaepektibo sa produksiyon ug kalidad.

Mga Kaayohan ug Gamit ang Application sa Automated Assembly Machines:

Alang sa mga Starters, Kini adunay potensyal sa pag-undang sa mga gasto sa labor. Automated Assembly Machines, Kung itandi sa tradisyonal nga manual nga katiguman, Mahimo nga makab-ot ang taas nga tulin ug episyente nga output samtang pagkunhod sa mga pamaagi sa manual ug mga kinahanglanon sa kawani.

Segundo, Ang mga awtomatiko nga mga makina sa asembliya adunay potensyal nga mapaayo ang pagkamakanunayon sa produkto ug kalidad. Tungod sa eksaktong katakus sa pagpahimulos sa makina ug pagpugong, Ang matag produkto mahimong magtigum sa parehas nga mga sukdanan, Ang pagkunhod sa mga sayup nga gipahinabo sa mga pamaagi sa manual.

Ikatulo, Ang mga awtomatiko nga mga makina sa asembliya makapadako sa pagka-flexible sa produksiyon ug kasagarang. Ang mga awtomatik nga mga makina sa asembliya mahimo nga ipahiangay sa mga panginahanglanon sa asembleya sa lainlaing mga butang pinaagi sa programming ug pag-configure sa daghang proseso, ug dali ra nila mabag-o ug mapaayo ang proseso.

Paggamit mga lugar sa mga awtomatiko nga mga makina sa asembliya:

Ang mga awtomatik nga mga makina sa asembliya gigamit sa lainlaing industriya, lakip ang mga butang nga elektrikal, Mga bahin sa Sasakyan, ug mga gamit sa balay. Ang mga awtomatik nga mga makina sa asembliya sa industriya sa electronics mahimong magtigum ug makonekta ang mga tabla sa sirkito, Pagpalambo sa pagkaayo sa paghimo ug kalig-on sa produkto. Sa sektor sa automotive, Ang mga awtomatik nga mga makina sa asembliya makahimo sa bahin sa Assembly ug Assembly, Pagdugang sa Paggasto sa Produksyon ug kalidad. Ang mga awtomatiko nga mga makina sa asembliya sa industriya sa domestic appliance mahimong makompleto ang asembliya ug pag-debug sa mga gamit sa panimalay samtang nag-ayo sa pagkamakanunayon sa produkto ug kalidad.

Sa pagtapos, Ang usa ka awtomatik nga tig-assisa nga makina usa ka labi ka episyente ug intelihente nga kagamitan nga makahatag hinungdanon nga mga benepisyo ug pag-adjust sa produksiyon. Pinaagi sa mga teknolohiya sa programming ug automation, Nakab-ot niini ang taas nga tulin, Taas nga kalidad nga asembliya sa produkto pinaagi sa paggamit sa mga modernong sensor, aktuator, ug mga sistema sa pagpugong. Uban sa padayon nga pag-uswag sa syensya ug teknolohiya, Ang paggamit sa mga awtomatikong mga makina sa asembliya mahimong labi ka kasagaran, pagdala bag-ong mga oportunidad ug kalisud sa pag-uswag sa industriya sa paghimo.

Gisunod namon ang kalidad sa una ug serbisyo sa una nga baruganan, ug paningkamoti nga makab-ot ang labing kaayo nga kalidad sa produkto ug serbisyo samtang nagpabilin nga realistiko, kontra, ug pagduso sa kadako.