Eguneroko ontzien industrian, -a Trigger ihinztagailua ezinbestekoa da: bere funtzionaltasunak produktua benetan nola erabiltzen den agintzen du.

Azken kontsumitzaileek sarritan ihinztagailu baten frustrazioa jasaten dute, isurtzen, edo garbigarri botila amaitu baino lehen hautsi. Esperientzia eskas batek zuzenean kaltetzen du marka baten ospea.

Songmilen, sakon ulertzen dugu min-puntu hori. Horregatik, gure ekoizpena estandar zorrotzei eusten diegu: Songmile ihinztagailu guztiek gainditzen dutela bermatuz 3,000 prentsa eta errebote zikloak.

Beraz, nola egiten du zehazki Songmilerena Trigger ihinztagailua iraunkortasun maila hori lortu?

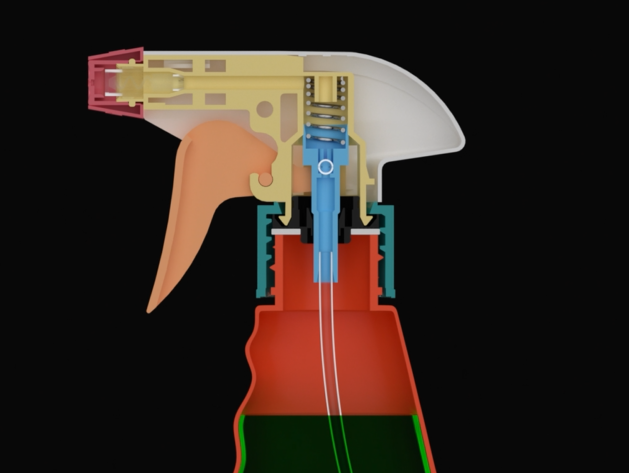

1.Anatomia: Zehaztasuna zati guztietan

Nahiz eta a ihinztagailu abiarazlea itxura sinplea izan daiteke kanpotik, ren muntaia da benetan zehaztasuneko hamar osagai baino gehiago. Bizi-iraupena lortzeko 3,000+ zikloak, zati bakoitzak koordinazio ezin hobean funtzionatu behar du.

Pistoia

Hau da presioa sortzen duen osagai nagusia. If the friction between the piston and the cylinder wall is too high, the pressing action feels stiff; if it is too low, the pressure will be insufficient, resulting in a weak spray. Southmile utilizes high-precision injection molds to control tolerances at the micron level, ensuring the piston remains smooth and perfectly sealed even after thousands of friction cycles.

The Spring

This is the critical component that determines the sprayer’s lifespan. Many inferior sprayers use ordinary steel, which rusts upon contact with liquid or loses resilience after just a few hundred presses. We use high-grade 304 edo 316 stainless steel springs. Not only do they offer superior corrosion resistance, but they also undergo strict tension testing to ensure the rebound force remains as strong as new after 3,000 zikloak.

The Glass Ball/Valve

This controls the direction of the liquid flow. If the glass ball lacks perfect sphericity or the valve seat is uneven, it leads to backflow or an inability to draw liquid. Our glass spheres are perfectly round, guaranteeing precise dispensing with every press.

The Gasket

This is the final line of defense against leakage. We employ materials with high elasticity to ensure a tight seal between the sprayer and the bottle neck. This guarantees zero leakage, even under transportation vibrations or when the bottle is inverted.

2.How do we ensure a lifespan of 3000+ zikloak?

True Produktuen bilaketa stems from our relentless dedication to materials and craftsmanship.

I. Refusing Recycled Materials,Insisting on Virgin Material

The toughness of the plastic has a direct impact on the product’s longevity. To save money, merkatuan dauden hainbat ihinztagailuek material birziklatuaren ehuneko handia dute. Honek plastikoa hauskorra bihurtzen du eta erabileran zehar hautsi daiteke, bereziki abiarazlearen konexio puntutik gertu. Erabiltzen tematzen gara 100% PP material birjina tentsioa jasaten duten osagai garrantzitsuetarako, maiztasun handiko erabilera jasateko egiturazko erresistentzia nahikoa dela ziurtatzea.

II. Zehaztasun-moldeen mantentze-lanak

Moldea da “ama” produktuarena. Gure ihinztagailuaren osagai guztiak erabiliz fabrikatzen direlako injekzio-moldaketa, Moldearen gainazaleko edozein zimurtasunak piezak sortzen ditu “errebak” (ertz zakarrak), horrek isurketa edo blokeatzea ekar dezake. Zorrotz jarraitzen ditugu moldeen mantentze- eta leuntze-prozedura erregularrak, ekoitzitako osagarri guztiak leunak direla ziurtatzeko, zehatza, eta akatsik gabekoa.

III. Laborategiko Proba Zorrotzak

- Nekearen proba automatikoa: Simulates high-frequency manual pressing over thousands of continuous cycles to observe for any jamming, breakage, or spring failure.

- Vacuum Leak Tester: We utilize multiple vacuum chambers to simulate various pressure scenarios, strictly verifying the sealing performance.

- Spray Pattern Testing: Ensures that the spray performance of the mass-produced goods delivered to you is perfectly consistent with the approved samples.

3.Why Durability Matters for Your Brand

-An 2025 and beyond, the packaging market will turn toward sustainability eta reusable systems.

Consumers are increasingly purchasing “Refill Packs” and recycling their original spray bottles. This adjustment throws a significant pressure on the ihinztagailu abiarazlea. A sprayer must now last for two, three, or four refills, not simply one bottle of liquid.

By choosing Songmile’s high-durability sprayers, you are:

- Supporting the Refill Economy:Enabling your clients to reuse your packaging with confidence.

- Protecting Brand Loyalty:Providing a quality experience every time a customer uses your product.

- Reducing Waste:A long-lasting sprayer results in fewer broken plastic parts ending up in landfills.

-A ihinztagailu abiarazlea is a little device that requires extensive engineering. It combines material science, mold precision, and fluid dynamics.

Songmile manufactures consistency rather than merely plastic bits.

Are you ready to improve your packaging reliability? Contact us immediately to acquire a sample kit and experience the “Songmile Smoothness” for yourself.