When you choose a pamu ni ilumu, you want the same smooth flow, the same dosage and no leaks every time. For us making sure this happens across millions of lotion pumps is not by accident. It’s a system of checks we’ve built step by step, like layers of protection to keep quality steady.

First Step, Raw Materials Check

Before assembling into a pamu ni ilumu, we test the raw materials first because bad pumps mean bad raw materials. Every batch of PP plastic and stainless steel springs needs to check. For PP plastic, we check whether its strength and color meet the standards. For springs, we test whether they can be repeatedly stretched and rebounded without breaking. If even one batch of products fails these simple tests, we will return it.

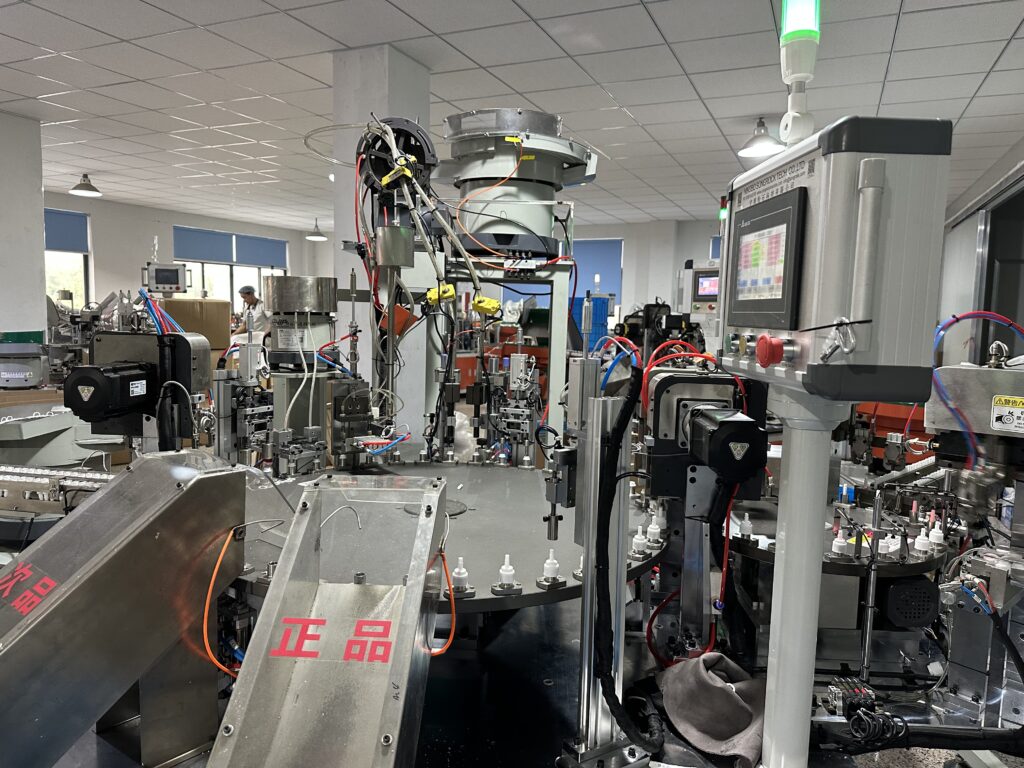

Second Step, Auto Production

Making pamu ni ilumu by hand would make lots of small mistakes, like parts put in wrong place or lotion pumps are too loose. That’s why we use assembly machines. Machines can do all the work, they follow the same steps day by day, effectively reduced the error rate.

But we don’t just let machines run alone. We have online testing tools that watch details in real time. Me kena ivakaraitaki, the sensor checks if the lotion pump’s size is the right size. Another tool measures the lotion pump head height to ensure it fits a standard sized.

Third Step, Final Quality Check

Even after production, every batch of pumps needs to do the final exam. Here’s what we do.

Press Life Test, We press the pump over and over to see if it’s still works. If gets stuck or stop pumping, it fails.

Vacuum Leak Test, We put the pump with bottle in a sealed container and suck out the air. If the liquid in the bottle leaked out , we will reject those pumps.

Pump Dosage Test, We measure exactly how much product comes out with each press. It needs to be the same every time to match customers expect.

Only the batches passed all these tests then we can shipped them out.

We promise no accident just reliable pumps

Our whole quality system is built to one goal, when you buy our lotion pumps, you never have to worry about the quality. No leaks, no stuck pumps, no wrong sizes.

Want to know more about how we check quality? Ask us for our Quality Control Manual we’re happy to share all the details.