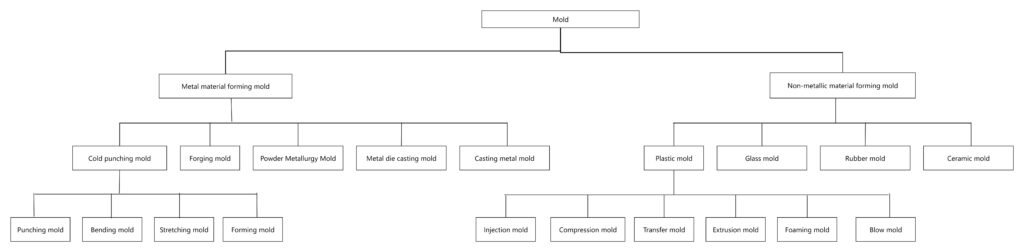

Ma'anar mold

Kayan aiki ne na musamman don ƙirƙirar sassan samfuran kuma babban kayan aiki ne a masana'antu.

Dangane da ƙamus na masana'antu na inji, wani mold ne na'urar da ke sarrafa sifa da girman abin samarwa.

Ana amfani da molds tare da samar da kayan aiki don sassan karfe kamar hatimi, Kagaji, extrusion, da jefa, ko tare da samar da kayan aiki don sassan da ba na ƙarfe ba kamar robobi, roba, da yurer. Suna iya ƙirƙirar ɗakunan ƙarfe da kuma sassan da ba na ƙarfe ba. Ya zama hanya mai mahimmanci a cikin masana'antun masana'antu na zamani.

An kafa sassan da aka samu ta hanyar molds “Workpie” (kamar sassan pouped, Abubuwan da aka ƙirƙira, filastik kayayyakin, manajojin, da dai sauransu.).

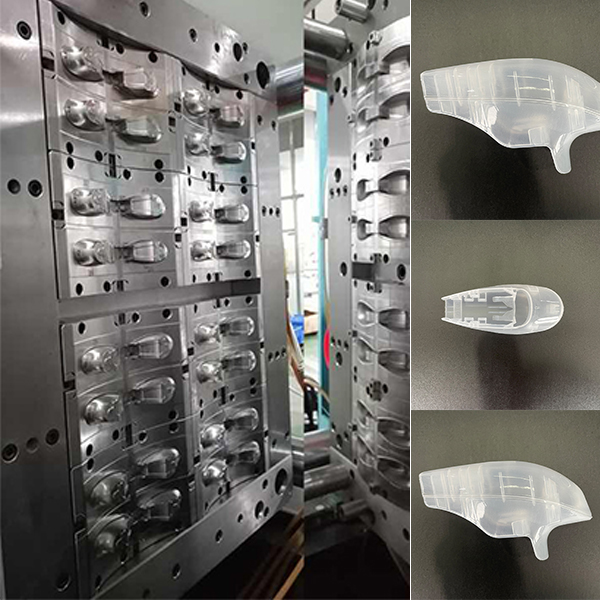

Molds da kayayyakin

Gabaɗaya, Samun kayan marufi yana farawa daga siyan kayan abinci, kuma ta hanyar hadin gwiwar molds da kayan aiki, An kafa samfuran samfuran. Sa'an nan, Bayan jiyya da kayan ado, An kammala samfuran da aka gama. Tsakanin su, Tsarin tsari na molds shine mayar da hankali ga wannan aikin.

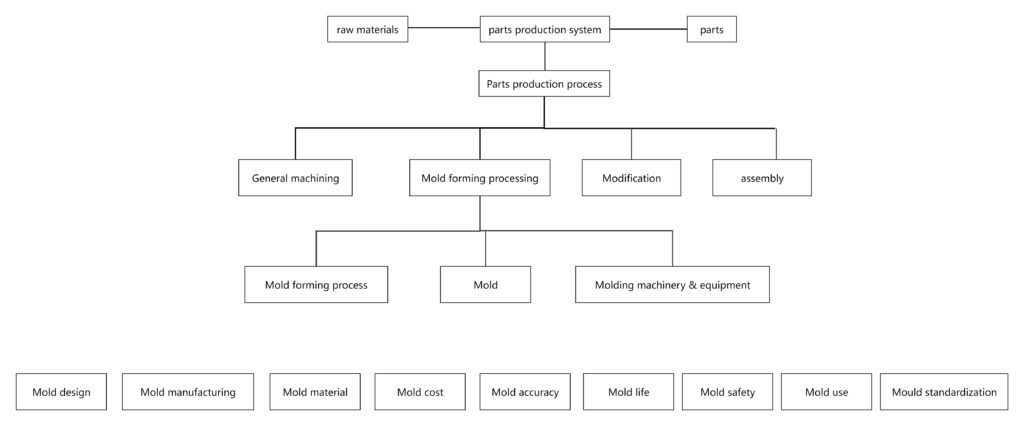

M

Za a iya rarraba molds dangane da kayan daban-daban na samfuran samfuran don kerarre, da kayan molds da kansu ma sun bambanta. Galibi ana tsara su gwargwadon kayayyakin. Daban-daban kayan da tafiyar matakai kai tsaye ka tantance kudin molds.

Dangane da kayan da ake samu, Za'a iya raba molds zuwa molds molds da m m m karfe. Za a iya inganta m ƙarfe na ƙarfe a cikin tsararren molds (Don baƙin ƙarfe mara nauyi-sittin da ƙarfe) da kuma m molds, da dai sauransu. Za'a iya raba m m m karfe cikin filastik molds da kuma m m molds. Kuma bisa abubuwa daban-daban na molds da kansu, ana iya rarrabe su azaman molds, m molds, vursuum molds, da kakin zuma molds, da dai sauransu.

Tsakanin su, tare da saurin cigaban matsalolin, Filastik filastik suna da alaƙa da rayuwar mutane.

Za'a iya rarrabe filastik na filastik gaba ɗaya azaman alluna masu gyara, iska mai ƙarfi mold, gas-taimaka gyara molds, da dai sauransu.

Tsarin masana'antu

Na farko, don yin mold, Dole ne a sami zane. Kuna buƙatar ɗaukar ra'ayoyin a zuciyar ku kuma ku juya su cikin tsari. Wannan shine inda ake shigowa. Prototypes canza tunanin ku cikin abu mai lalacewa. Kuna iya sauƙaƙe ya zama cikakke gwargwadon hangen nesa. Da zarar an yi prototype, An aiko shi zuwa masana'antar morcin ƙwararru. Daga nan sai masana'anta ta tura shi zuwa kamfanin dubawa don bincika girman. Waɗannan sune ainihin bayanan don yin ƙiyayya. Kawai tare da waɗannan bayanan za a iya yin saiti na prototype. Bayan an gama binciken, Injiniyan zane mai zane yana amfani da software na ƙwararru kamar autocad da Pro / E don tsara shi. A lokaci guda, Hakanan ana aiwatar da wasu ayyuka, Irin su zabar ƙyallen karfe don mold.

Bayan an zabi karfe, Kawai tarin baƙin ƙarfe ne kuma ba mold ba. Yana buƙatar aiwatar da shi don zama mold. Lokacin da karfe aka saya, Ba za a iya sarrafa shi ba da gangan. Yana buƙatar aiwatar da daidai, kuma mafi girman daidaito, mafi kyau. Yau da kullum, Mafi fasaha na fasaha na iya samar da molds tare da kuskure kawai 'yan microns. Duk da haka, Irin waɗannan molds suna da tsada. Suna buƙatar ƙwararrun ƙarfe mai ƙarfi da haɓaka, wanda sau da yawa ana biyan kuɗi sama da miliyan. I mana, Ba tare da masu fasaha ba, Dukkan abu ne a banza.

Na biyu, Bayan zabar karfe, Aikin ya fara. 'Yan masu sana'a suna aiwatar da kowane ɓangare na ƙirar da ke cikin zane-zane ta amfani da injunan da yawa (kamar lateres, filo, injin niƙa, grinders, injunan fitowar lantarki, Kayan waya, da cibiyoyin kwastomomin CLN CNC). Sa'an nan, sassan sun hallara kuma sun lalace.

Don molds tare da sauki cavities da stores, mai shirin rubutu na CNC ya rubuta shirin kuma yana amfani da na'urar CNC don aiwatar da mold. Don wuraren da ba za a iya sarrafa su ta inji CNC ba, An yi amfani da injin lantarki na lantarki don aiki. Don molds tare da hadaddun kafafun saman, Ana amfani da na'urori na CNC guda uku don aiki. An samar da shirin NC wanda aka samo a kan samfurin 3D a cikin software na kamforar kamshin sana'a.

Daga karshe, Bayan an gama gyaran, An aiko shi ne don tsananin yanayin. Da zarar an sami salo mai nasara, Za a iya fitar da mold.

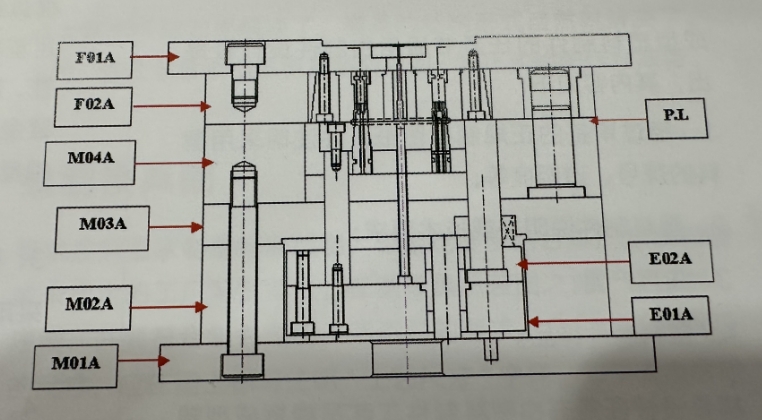

| F01A | Farantin gyara | E02b | Bututu jacking | E01A | Ƙananan ejector |

| F02A | Samfuri na Jagora | E02C | Dawo da fil | O02a | Farantin Eject |

| M01A | Ƙananan gyara farantin | P01A | Mai haɗawa Feed | F | Mai tsaron baya |

| M02aaa | A tsaye farantin | P02A | Gudummawa | M | Mallin mold |

| M03A | Appilary farantin | P03A | Jagorar hatimi | P.L | Tsarin aiki |

| M04a | Male nika farantin | P04a | Guide na Sleeve |

Aikace-aikacen mold

Ana amfani da molds sosai a cikin masana'antar kayan kwalliya na kwaskwarima. Filastik kayayyakin, Gilashin Gilashin, da samfuran takarda duk suna buƙatar molds. Kudin molds kai tsaye yana tantance farashin kayan marufi da kuma lokacin bayarwa na kayan tattarawa. Saboda haka, Don kayan tattarawa, Molds sune ainihin da asali.