Definisyon mwazi

Yon mwazi se yon zouti espesyalize pou fòme pati pwodwi e li se yon gwo ekipman pwosesis nan pwodiksyon endistriyèl.

Dapre diksyonè a nan pwosesis fabrikasyon mekanik, yon mwazi se yon aparèy ki kontwole fòm ak gwosè objè pwodiksyon an.

Mwazi yo itilize ak ekipman fòme pou pati metal tankou Stamping, fòje, ekstrizyon, ak depoze, oswa ak ekipman fòme pou pati ki pa metalik tankou plastik, kaoutchou, ak seramik. Yo ka kreye yon gran varyete metal ak pati ki pa metalik. Li te vin tounen yon metòd pwosesis enpòtan nan pwodiksyon endistriyèl modèn.

Pati ki fòme pa mwazi yo anjeneral rele “pyès travay” (tankou pati so, pati fòje, pwodwi plastik, depoze, elatriye.).

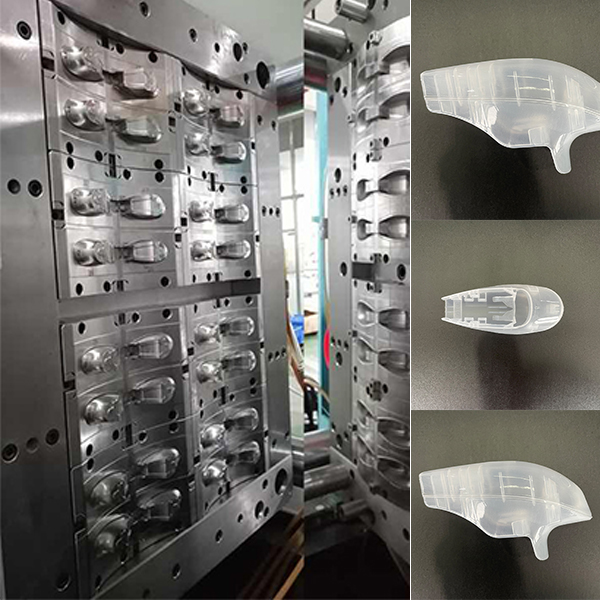

Mwazi ak pwodwi yo

Anjeneral, pwodiksyon an nan materyèl anbalaj kòmanse nan akizisyon an nan matyè premyè, ak atravè koperasyon nan mwazi ak ekipman, pwodwi yo fòme. Atò, apre tretman sifas ak dekorasyon, pwodwi fini yo fini. Pami yo, pwosesis la fòme nan mwazi se konsantre nan pwosesis sa a.

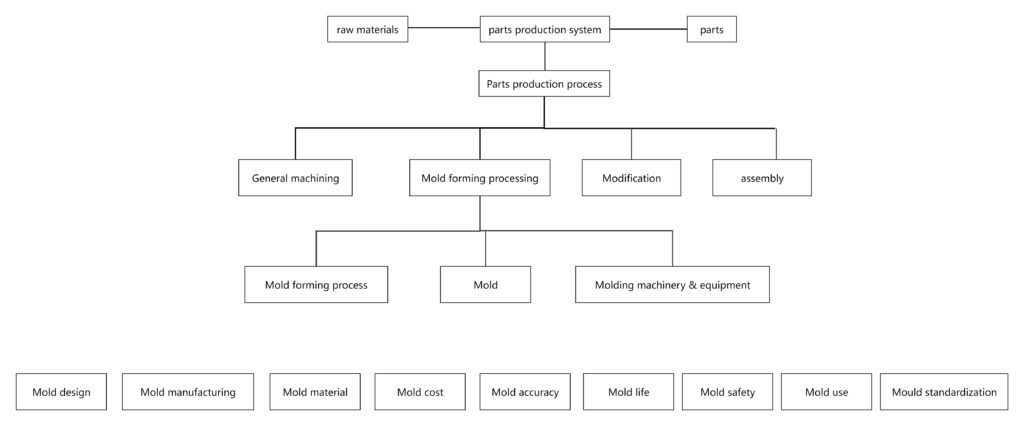

Klasifikasyon mwazi

Mwazi yo ka klase dapre diferan materyèl pwodwi yo itilize pou fabrike, ak materyèl yo nan mwazi yo tèt yo tou divès. Yo sitou Customized dapre pwodwi yo. Diferan materyèl ak pwosesis dirèkteman detèmine pri a nan mwazi yo.

Dapre materyèl yo te fòme, mwazi yo ka divize an mwazi metal ak mwazi ki pa metal. Mwazi metal yo ka plis klase nan mwazi Distribisyon (pou metal ki pa FERROUS die-casting ak depoze asye) ak fòje mwazi, elatriye. Mwazi ki pa metal yo ka divize an mwazi plastik ak mwazi inòganik ki pa metal. Ak ki baze sou materyèl yo diferan nan mwazi yo tèt yo, yo ka klase kòm mwazi sab, mwazi metal, mwazi vakyòm, mwazi sir, elatriye.

Pami yo, ak devlopman rapid nan plastik segondè-molekilè, mwazi plastik yo gen rapò ak lavi moun.

Mwazi plastik yo ka jeneralman klase kòm mwazi bòdi piki, mwazi ekstrizyon bòdi, mwazi bòdi asistans gaz, elatriye.

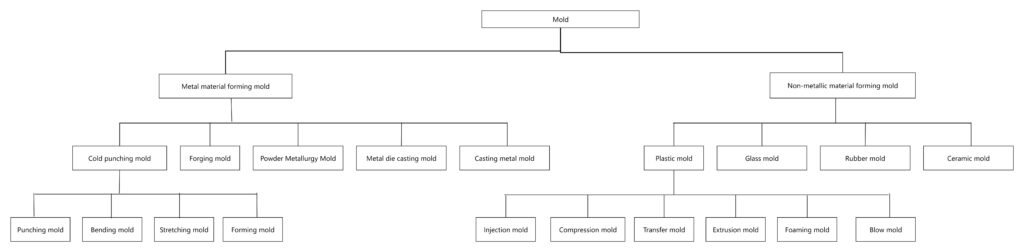

Pwosesis Faktori Mwazi

Premye, fè yon mwazi, dwe gen yon konsepsyon. Ou bezwen pran lide yo nan tèt ou epi fè yo tounen yon konsepsyon. Sa a se kote pwototip antre. Pwototip transfòme imajinasyon ou an yon objè byen mèb. Ou ka fè li pi pafè selon vizyon ou. Yon fwa ke pwototip la fini, li voye nan yon faktori mwazi pwofesyonèl. Lè sa a, faktori a voye li bay yon konpayi optik pou eskane dimansyon yo. Sa yo se done prensipal yo pou fè mwazi an. Se sèlman ak done sa yo ka yon kopi pwototip la dwe fè. Apre optik la fini, enjenyè konsepsyon mwazi an sèvi ak lojisyèl pwofesyonèl tankou AutoCAD ak Pro / E pou konsepsyon li. An menm tan an, lòt travay yo fèt tou, tankou chwazi vid asye pou mwazi an.

Apre yo fin chwazi asye a, li se jis yon pil fè epi li pa yon mwazi. Li bezwen trete yo vin yon mwazi. Lè yo achte asye a, li pa ka trete owaza. Li bezwen trete jisteman, ak pi wo a presizyon, pi bon an. Kounye a, teknoloji ki pi avanse ka pwodwi mwazi ak yon erè nan jis kèk mikron. Poutan, mwazi sa yo chè. Yo mande pou bon jan kalite asye ak machin avanse, ki souvan koute plis pase yon milyon. Natirèlman, san travayè kalifye, se tout pou gremesi.

Dezyèmman, apre chwazi asye a, travay la kòmanse. Travayè kalifye travay chak pati nan mwazi an dapre desen yo lè l sèvi avèk machin divès kalite (tankou tour, plenn, machin fraisage, moulen, machin egzeyat elektrik, kouto fil, ak sant D' CNC). Atò, pati yo reyini ak debogaj.

Pou mwazi ki gen kavite senp ak nwayo, yon pwogramè CNC ekri pwogram nan epi sèvi ak yon machin CNC pou trete mwazi an. Pou zòn ki pa ka trete pa machin CNC la, se yon machin egzeyat elektrik itilize pou pwosesis. Pou mwazi ak sifas koube konplèks, se yon machin CNC twa-aks yo itilize pou pwosesis. Pwogram NC a te pwodwi ki baze sou modèl 3D nan lojisyèl pwofesyonèl CAM.

Anfen, apre mwazi an fini, li voye pou esè bòdi. Yon fwa bòdi jijman an gen siksè, mwazi an ka lage.

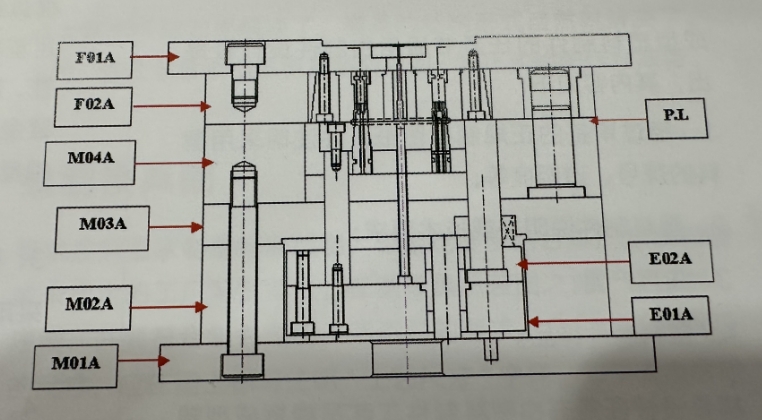

| F01A | Upper Fixing Plate | E02B | Tiyo Jacking | E01A | Anba Plak Ejector |

| F02A | Modèl Mèt | E02C | Retounen PIN | O02a | Anwo Plak Ejector |

| M01A | Lower Fixing Plate | P01A | Feed Connector | F | Mèt Mwazi |

| M02aaa | Plak kanpe | P02A | Lokalize bag | M | Mwazi Gason |

| M03A | Plak oksilyè | P03A | Gid Poto | P.L | Mwazi sistèm separe |

| M04A | Plak Manje Gason | P04A | Gid Pin manch |

Aplikasyon mwazi

Mwazi yo lajman ki itilize nan endistri materyèl anbalaj kosmetik. Pwodwi plastik, pwodwi vè, ak pwodwi papye tout mande pou mwazi. Pri a nan mwazi dirèkteman detèmine pri a nan materyèl anbalaj ak tou tan an livrezon nan materyèl anbalaj. Se poutèt sa, pou materyèl anbalaj, mwazi yo se nwayo a ak fondamantal.