カビの定義

金型は、製品部品を形成するための特殊なツールであり、工業生産における主要なプロセス機器です.

機械的製造プロセスの辞書によると, 金型は、生産オブジェクトの形状とサイズを制御するデバイスです.

金型は、スタンピングなどの金属部品のための形成機器で使用されます, 鍛造, 押し出し, キャスト, または、プラスチックなどの非金属部品のための機器の形成, ゴム, とセラミック. 彼らは多種多様な金属と非金属の部品を作成できます. 現代の工業生産において重要な処理方法になっています.

金型で形成される部品は通常、呼ばれます “ワークピース” (スタンプ部品など, 鍛造部品, プラスチック製品, キャスティング, 等).

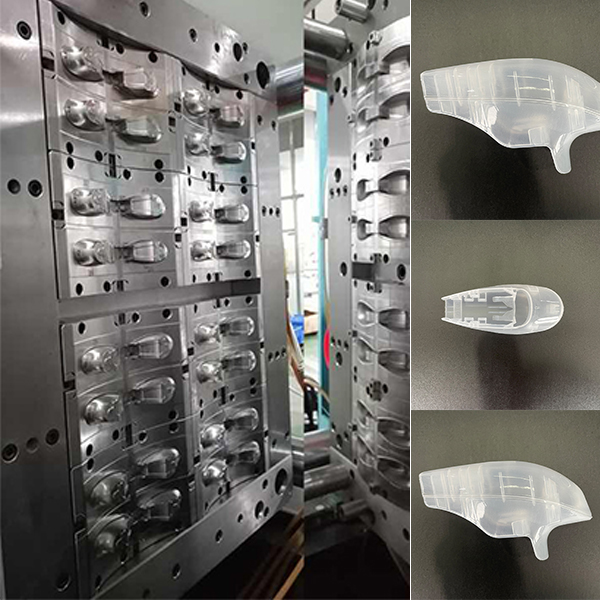

カビと製品

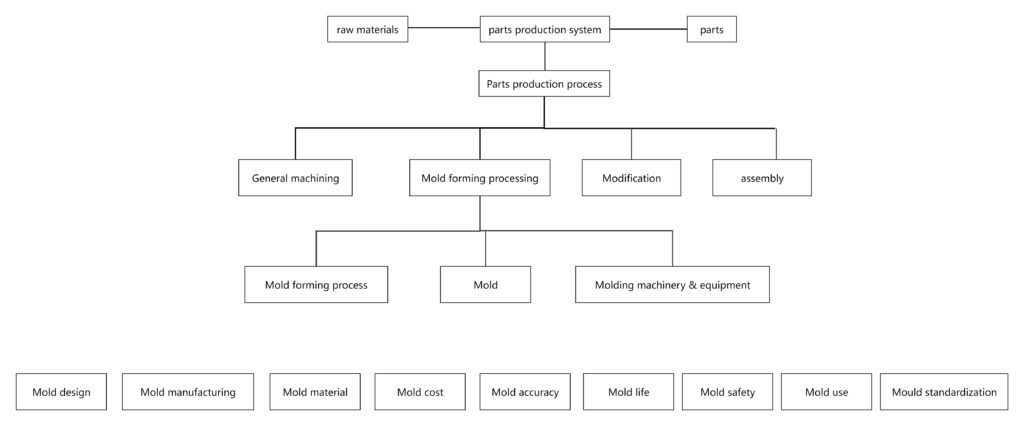

一般的に, 包装材料の生産は、原材料の調達から始まります, そして、金型と機器の協力を通じて, 製品が形成されます. それから, 表面処理と装飾の後, 完成品が完成しました. その中で, カビの形成プロセスはこのプロセスの焦点です.

金型分類

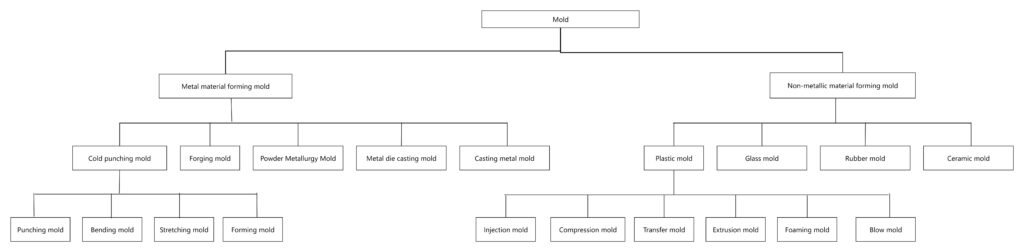

金型は、製造に使用される製品のさまざまな材料に基づいて分類できます, そして、カビ自体の材料も多様です. それらは主に製品に従ってカスタマイズされています. 異なる材料とプロセスは、金型のコストを直接決定します.

形成されている資料によると, カビは金属型と非金属型に分けることができます. 金属型は、さらに分類され、鋳造型に分類できます (非鉄金属ダイキャスティングおよびスチール鋳造用) そして、型の鍛造, 等. 非金属型は、プラスチック型および無機非金属型に分けることができます. そして、金型自体のさまざまな材料に基づいて, それらは砂型に分類できます, 金属型, 真空型, ワックス型, 等.

その中で, 高分子プラスチックの急速な発展により, プラスチック型は、人々の生活に密接に関連しています.

プラスチック型は通常、射出成形金型に分類できます, 押出成形金型, ガス支援成形金型, 等.

カビ製造プロセス

初め, 型を作るために, デザインが必要です. あなたはあなたの心の中でアイデアを取り、それらをデザインに変える必要があります. これがプロトタイプが登場する場所です. プロトタイプは、想像力を有形のオブジェクトに変換します. あなたはあなたのビジョンに従ってそれをより完璧にすることができます. プロトタイプが完了したら, プロの金型工場に送られます. その後、工場はそれをスキャン会社に送り、寸法をスキャンします. これらは、金型を作成するための主要なデータです. これらのデータでのみ、プロトタイプのレプリカを作成できます. スキャンが完了した後, 金型デザインエンジニアは、AutoCADやPro/Eなどのプロのソフトウェアを使用して設計しています. 同時に, 他のタスクも実行されます, 金型用のスチールブランクの選択など.

鋼が選択された後, それはただの鉄の山であり、型ではありません. 型になるために加工する必要があります. 鋼が購入されたとき, ランダムに処理することはできません. 正確に処理する必要があります, そして、精度が高いほど, より良い. 現在, 最先端のテクノロジーは、わずか数ミクロンのエラーで金型を生成できます. でも, そのような型は高価です. 高品質のスチールと高度な機械が必要です, 多くの場合、100万人以上の費用がかかります. もちろん, 熟練した労働者なし, それはすべて無駄です.

第二に, 鋼を選択した後, 作業が始まります. 熟練労働者は、さまざまな機械を使用して図面に従って金型の各部分を処理します (旋盤など, フラット, ミリング機, グラインダー, 電気排出機, ワイヤーカッター, およびCNC加工センター). それから, 部品は組み立てられてデバッグされます.

単純な空洞とコアを持つ型用, CNCプログラマーがプログラムを書き、CNCマシンを使用して金型を処理します. CNCマシンで処理できないエリア向け, 電気排出機が処理に使用されます. 複雑な湾曲した表面を持つ型の場合, 3軸CNCマシンが処理に使用されます. NCプログラムは、プロのCAMソフトウェアの3Dモデルに基づいて生成されます.

ついに, 型が完成した後, トライアルモールディングのために送信されます. トライアルモールディングが成功したら, 型を放すことができます.

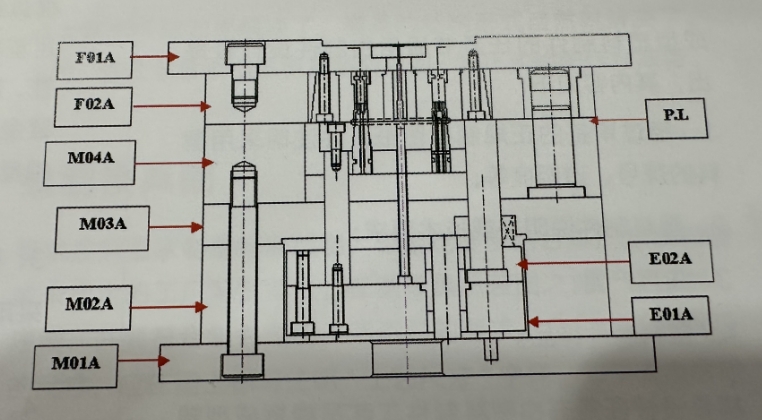

| F01A | 上部固定プレート | E02B | パイプジャッキング | E01A | 下部イジェクタープレート |

| F02A | マスターテンプレート | E02C | ピンを返します | O02a | アッパーエジェクタープレート |

| M01A | 下部固定板 | P01A | フィードコネクタ | f | マスター型 |

| M02AAA | スタンディングプレート | P02A | リングの位置 | m | 雄の型 |

| M03A | 補助プレート | P03A | 柱をガイドします | P.L | 金型別れシステム |

| M04A | オスの研削板 | P04a | ガイドピンスリーブ |

金型アプリケーション

金型は、化粧品包装材料業界で広く使用されています. プラスチック製品, ガラス製品, 紙製品にはカビが必要です. 金型のコストは、パッケージング材料のコストと包装材料の納期を直接決定します. したがって, 包装材料用, 金型は核と基本です.