Ko te pounamu-i runga i te pounamu e kiia nei ko te pounamu pōro, Ko te momo noa o te ipu kapi e whakamahia ana e te iwi. Ko te tinana o te raarangi i runga i te pounamu he mea hanga noa i te kirihou, i te karaihe ranei. Ko enei pounamu he iti te kaha o enei pounamu ka rite ki te poro porotaka i te tihi, tuku mo te tono, Te aukati i te riihi wai, me te whakarato i tetahi paanga whakarara. Ko te pōro o te rārangi i te tihi ka taea te hanga kirihou, te rino ranei. Ko te nuinga o nga pounamu kirihou e whakamahi ana i nga poro rino, Ahakoa he iti ake nga hua penei i te ngutu ngutu ka whakamahia he kirihou, Kei runga i te utu o te hua.

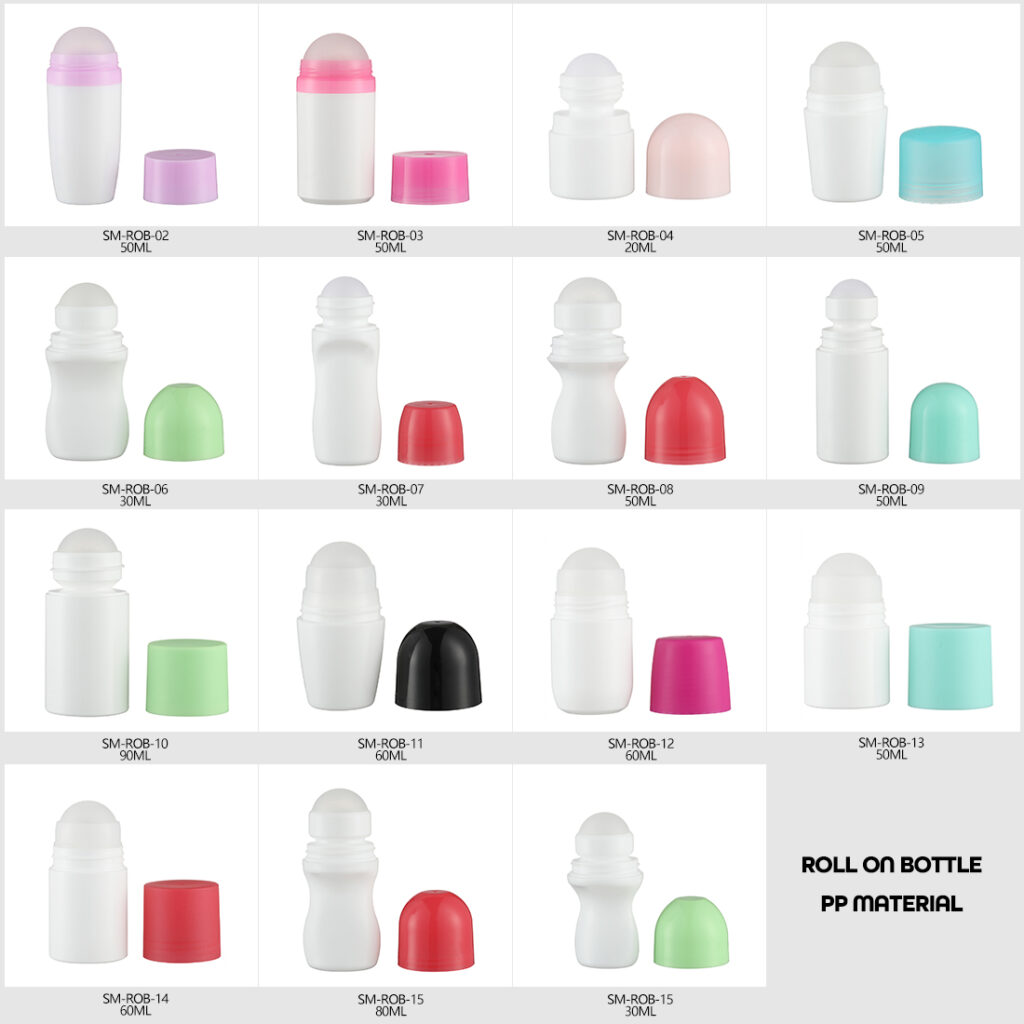

Nga taonga me nga waahanga o te raarangi i runga i te pounamu

Whakaritea ki nga puna, Hurihia i runga i te pounamu ka nui ake te tono o nga deodorant, te hinu tinana ranei i te kiri, ka waiho i te mate pai i muri i te hurihuri. Mo nga waahanga whakamahi, Hurihia nga hua ka nui ake ngaio. I roto ia ratou, Ka whakamahia te pukapuka kirihou ki nga ipu kirihou mo nga kirikiri kanohi, Whakahohehia te tono tika huri noa i te rohe o te kanohi mo te kapinga me te paanga whakarara hei awhina i nga kiro kanohi me te ngenge. Ko nga karaihe, ko nga poro raima ranei e whakarato ana i te tino whakamahana e te mate hei whakaiti i te whakakaha me te tuku i te waatea ki te whakamahi.

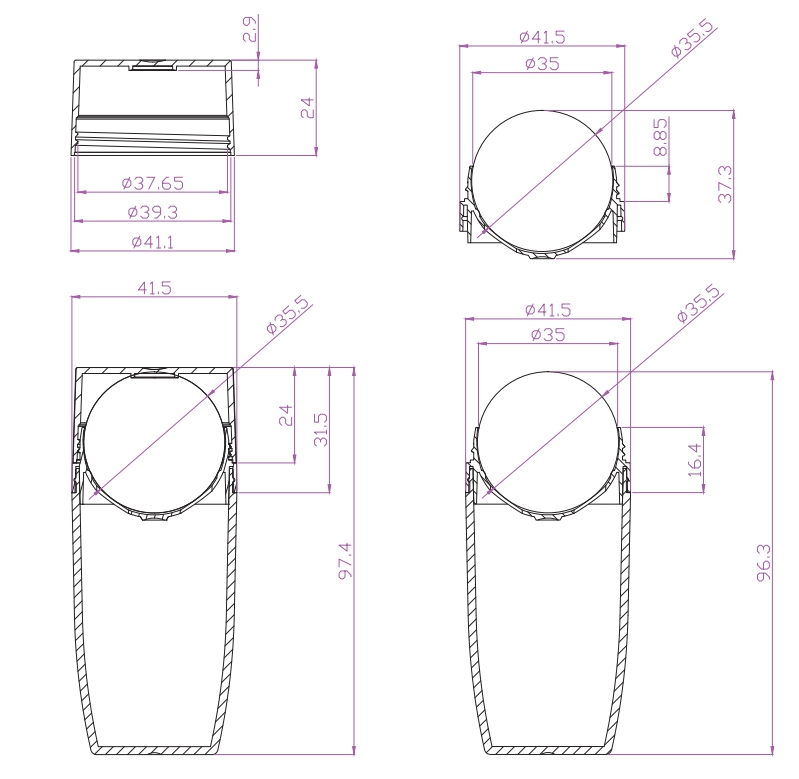

Ko te pukapuka kirihou i runga i nga pounamu ka tohatoha i etahi ahuatanga me te karaihe, pēnei i te tauhohenga iti me nga kaupapa, I te wa e heke mai ai te ngoikore o te karaihe i runga i nga pounamu i te wa o te waka. Ka taea e te raima kirihou i runga i nga pounamu te whakatipu-i hangaia i roto i nga momo tae me te mutunga, tae atu ki nga tohu kirikiri ranei, Te tuku utu iti rawa me te kore e whakaitihia te kounga. Ko te mea nui o te raarangi i runga i nga pounamu ko o raatau kukume wai whai hua i te wa e whakamahia ana me te kore e whakamahia. Ko nga hua ka pa ki te waatea i mua i te wehe i te wheketere, te whakarite kia kaua e raru nga take me te whakamahinga kore-awangawanga.

Nga tono o te hurihuri i runga i nga pounamu

Ka whakamahia noatia ratou mo nga kohinga kakano penei i nga kirikiri kanohi, kakara, ngutu ngutu, Te Raru o te tinana, kiri kirihou, hinu faufaa, maimoatanga hakihaki, Nga rongoā anti-itch, Nga rongoā, Te whakamarumaru, me nga hua a nga tamariki. Ko te Parmaceutical Parmaceutical tetahi atu waahanga tono nui mo te hurihuri. Hei kaiwhakarato mo nga kao makariri, Ka taea e ratau te tono o te kiri rongoa i runga i te kiri e hiahia ana i te wera wera, Ahakoa te whakamarumaru o te whakamahana i nga awhina ki te whakaheke i te kirika. Ma tenei ka karo i te ngoikoretanga i whakahekehia e nga tikanga whakamahana tinana tuku iho, ka pai ake te koretake o te tono a-ringa.