Product Definition

Trigger Sprayer depending on the composition of the liquid in the container, trigger sprayer can be used in various fields such as gardening, cleaning, haircare, and beauty. The most common manual sprayers feature a trigger or push-button structure, where pressing the trigger or nozzle switch atomizes and sprays the liquid from the container.

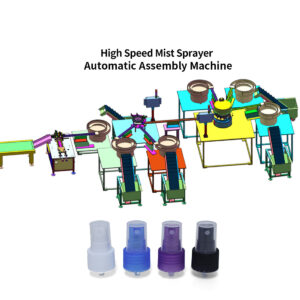

Manufacturing Process

The main components of a trigger sprayer are primarily made of plastics such as ABS, PP, PE, and EVA. Some are coated with an aluminum shell or metallized film. These components are mainly formed through injection molding. Key components, such as the cover, can undergo processes like electroplating, metallization, spray painting, or color injection molding.

Product Structure

1.Product Structure Display

2.Component Description

The existing trigger sprayer consists of an cover, spring, glass ball, gasket, closure, tube, nozzle, handle and piston, among other components.

3.Working Principle

When the handle is pressed, the piston slides upward within the piston chamber, drawing liquid through the suction tube. The liquid then passes through the gun body channel and the inner hole of the sealing component, where it is atomized and sprayed out through the distributor holes and nozzle cap. Releasing the trigger allows the piston to reset under the spring’s force. Continuous pressing and releasing of the trigger results in a steady mist-like spray.

Cosmetic Applications

Trigger Sprayers are primarily used in the personal care industry for liquid atomization, converting liquids into fine droplets. They are widely applied in household, agricultural, and medical settings for tasks such as watering plants, disinfection, pest control, and sanitation cleaning.

Purchasing Considerations

- Due to the large number of components, it is advisable to opt for standard molds when developing new trigger sprayer products to avoid high mold costs and long lead times.

- The connection between the body and the cover may not be sturdy, leading to shell detachment during use or transportation.

- The sealing component, originally a cylindrical rubber part, lacks resistance to aging, acids, and alkalis. At temperatures below 0°C, it hardens and loses its sealing function. Contamination by liquids can cause deterioration and corrosion, reducing the product’s lifespan and resulting in poor atomization with larger droplets.