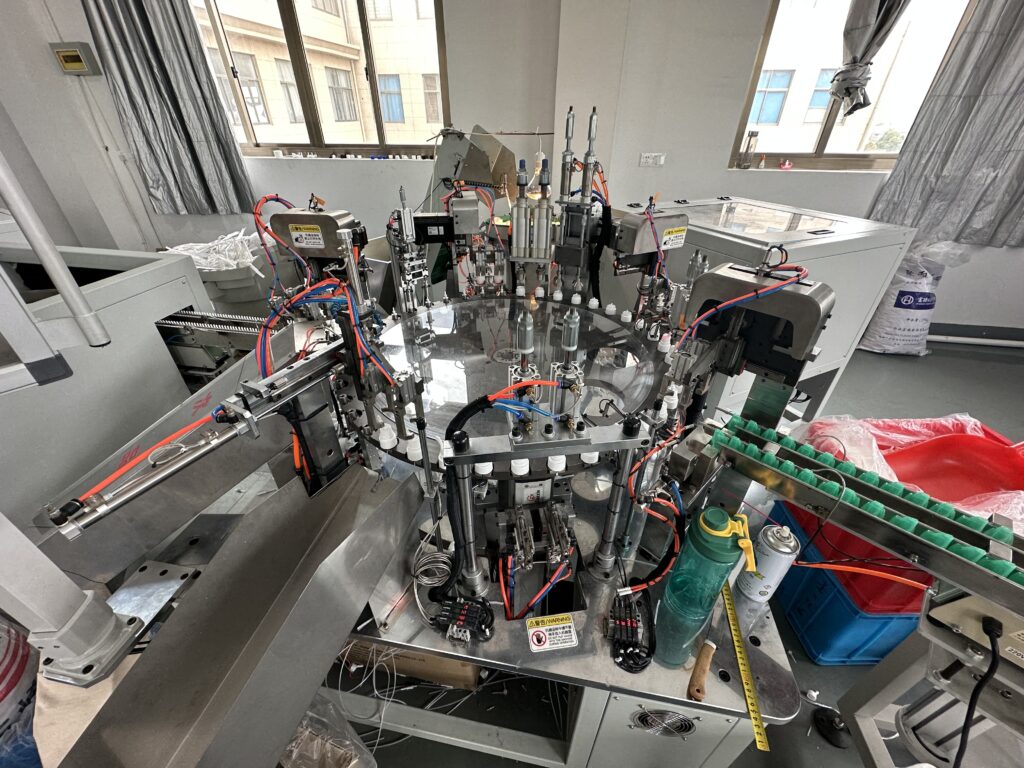

Eita noa tatou e hamani i te mau tao'a uraina, e hamani atoa râ tatou e e hamani atoa tatou i te mau matini hamaniraa uraina. I teianei, E hamani te taiete i te mau ravea no te putuputu i te mau taata i te mau mahana atoa mai te mau pupuhi hu'ahu'a, Te mau pâmu toto, fare ha'api'i., e te tahi atu â. Te tere nei te mau matini. Te aifaito - ore - raa, Te mau mana'o tauturu no te, te maniania raro roa, Te mau mana'o tauturu no te, e te hoê 99.9% Te mau mana'o tauturu no te haapiiraa. E mea aravihi e te aueue ore, e mea ohie ia faaohipa e ia tape'a, e ua amui i te tairururaa e te tamataraa. E nehenehe e ravehia te mau hoho'a i matauhia no te haamâha i te hinaaro o te feia hoohoo’ e hinaarohia te mau tauihaa huru rau e e faaiti mai i te numera o te feia rave ohipa i te tairururaa no te mau hoani. E faaiti atoa te reira i te mau haamâu'araa no te hamaniraa i te mau tao'a, faati'araa i te mau hoani ia faarahi i te faito moni e te mau haamau'araa.

Ua riro te hoê ravea haapurororaa i te hoê huru ravea aravihi o te faaohipa maitai i te mau matini roro uira, māuruuru, e te mau ravea no te hi'opoa i te putuputuraa o te mau tao'a na roto i te mau faanahoraa e te mau ravea aravihi apî. Te rahi noa ' tura te faaohiparaa i te mau ravea putuputuraa i roto i teie tau, Te mau maitai rahi e te mau haamaitairaa rahi.

Mai teie i muri nei, te mau ohipa e te mau ohipa a te rave'a putuputuraa.:

1.Te faatere nei te faanahoraa Conveyor i te mau tao'a haereraa mai te hoê ohipa i muri iho. No te faatupu i te hoê tauiraa rahi e te mau tao'a tahi, E pinepine te faanahoraa haapurororaa i te faaohipa i te mau ati, I tua, e aore râ, te mau mauhaa robota.

2.E faaohipahia te hoê faanahoraa no te faataa i te mau tao'a no te faataa i te mau huru e te vahi. E faataa te faanahoraa o te faanahoraa i te tapao aore ra te mau tuhaa i nia i te tao'a ma te faaohipa i te mau hoho'a, hō'ē, e aore râ, te hi'opo'araa i te barcode no te faatereraa i muri mai e te putuputuraa.

3.Te mafatu e te faanahoraa o te putuputuraa, o te mafatu ïa o te matini putuputuraa. No te faatupu i te faahopearaa hopea, e titauhia ia haaputuputu i te mau tuhaa huru rau. I roto i te mau faanahoraa, te vai ra te mau mauhaa robot i roto i te mau faanahoraa, ha'uti, e aore râ, te mau rave'a, I te tahi atu mau vahi, o te putuputu nei i te mau tuhaa taa ê i nia i te mau tiaraa taa ê ma te faaohipa i te hi'opoaraa i te tiaraa e te tauiraa.

4.Te faanahoraa hi'opoa, o te roro ïa o te ravea no te putuputu, e te hi'opoa ra oia i te ohipa taatoa a te ravea a te putuputuraa. PLC (Āmui'a) e aore râ, e nehenehe te mau rave'a no te faatere i te roro uira e faanahohia e e faaohipahia. E nehenehe ta ' na e hi'opoa i te huru o te mau tao'a atoa i te taime mau e e taui oioi noa i te reira ia au i te mau tao'a e te mau ture i faataahia no te haapapu i te tano e te vai - maitai - raa o te putuputuraa.

5.I te roaraa o te putuputuraa, te mau haamaramaramaraa e te mau haamaramaramaraa e hi'opo'a i te mau haamaramaramaraa e te mau haamaramaramaraa. I te taime a faaohipahia ' i te rave'a haaparareraa parau, e nehenehe te faanahoraa papa'iraa e te hi'opo'araa e papa'i i te mau rave'a e te mau tapa'o e rave rahi, Mai teie te anuvera, Pouhōʻā, Ra'ā, e te tahi atu â, ma te faaohipa i te mau rave'a e te mau rave'a hi'opo'araa. E nehenehe teie mau haamaramaramaraa e faaohipahia no te faarahi e no te haamaitai i te ohipa hamaniraa, no te faarahi i te aravihi o te hamaniraa e te huru.

Te mau tao'a e te faufaaraa o te mau matini roro uira:

No te haamata, no te haamata, a haamata, e nehenehe ta ' na e faaiti rahi i te mau haamâu'araa o te ohipa. Te mau rave'a haaparareraa parau, ia faaauhia i te putuputuraa a te rima tahito, E nehenehe te reira e faatupu i te mau rave'a aravihi e te aravihi ma te faaiti i te mau rave'a arata'iraa e te mau titauraa no te mau rave ohipa.

Ha'iti, E nehenehe te mau matini putuputuraa e haamaitai i te huru o te tao'a e te huru. No te mau aravihi mau o te matini e te mau aravihi no te faatere, E nehenehe te mau tao'a atoa e faataahia i te mau titauraa hoê â, te faaitiraa i te mau hape i tupu mai na roto i te mau raveraa a te rima.

Tātou, E nehenehe te mau matini putuputuraa e faarahi i te huru o te hamaniraa e te faito. E nehenehe te mau rave'a haaparareraa mana'o e au i te mau hinaaro o te mau tao'a e rave rahi na roto i te faanahoraa e te haamauraa i te mau rave'a e rave rahi, e e nehenehe ta ratou e taui e e haamaitai i te ohipa.

Te mau vahi o te mau matini putuputuraa autometed:

E faaohipahia te mau matini roro uira i roto i te mau fare hamaniraa tauihaa atoa, mai te mau tao'a uira, fa'a'ōfa'i, e te mau mauhaa. E nehenehe te mau matini roro uira tei î i te mau ravea uira e haaputuputu e e tuati i te mau iri haaati, te haamaitai i te aravihi no te hamani i te mau tao'a e te maitai o te tao'a. I roto i te tuhaa fenua, E nehenehe te mau matini putuputuraa auto e rave i te hoê tuhaa o te putuputuraa e te putuputuraa, te faarahiraa i te vitiviti e te huru. E nehenehe te mau matini putuputuraa i roto i te ohipa tapihooraa tauihaa i te fare e faatupu i te putuputuraa e te ino o te mau mauhaa o te fare ma te haamaitai i te huru o te mau tao'a e te huru.

I te pae hopea,, Ua riro te hoê matini putuputuraa aunoa ei ravea maitai roa e te aravihi roa o te nehenehe e horoa i te mau maitai rahi e te mau tauiraa rahi. Na roto i te mau rave'a aravihi no te faanahoraa e no te mau pereoo, E manuïa te reira i te mea e, e mea vitiviti roa te reira, Te putuputuraa rahi roa a'e na roto i te faaohiparaa i te mau rave'a no teie tau, māuruuru, e te mau faanahoraa. Na roto i te haamaitairaa tamau i te ihi e te mau rave'a aravihi, E riro mai te faaohiparaa i te mau matini putuputuraa aunoa ei mea matau - maitai - hia, te horo'araa i te mau rave'a apî e te mau fifi i te faahoturaa o te ohipa hamaniraa tauihaa.

Te pee nei matou i te parau tumu matamua e te taviniraa, e te hinaaro no te fana'o i te huru e te taviniraa maitai roa ' ' e, e te vai noa ra te reira, ha'api'ira'a, e te anaanatae i te rahi.