When you enter Songmile Packaging factory, what you’ll see is not just efficiently running equipment and neatly organized workshops—it’s an entire production system built around high quality. From automated machines that make sure things are precise, to checking quality every step of the way to catch flaws, to having enough production capacity to keep supplies steady—every part works to avoid problems like bad products and leaks. Let’s take you inside the factory to break down the hidden costs of low-quality trigger sprays, and show you why buying high-quality ones is such a smart business move.

1.Automated Production: Automated Production: Ua haapii mai te “Precision Guard” to Cut Defects from the Start.

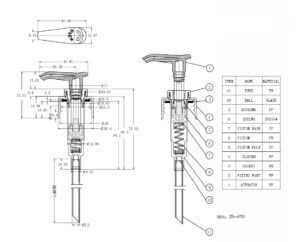

In our main production workshop, we have four automated Tuʻaʻa te mau reni no ta tatou mau tao'a atoa, e te vai-maitai-raa o te mau mimimetera - teie ta tatou rave'a matamua no te faaore i te mau hape. Te faaohipa nei matou i te mau rave'a no te hi'opo'a i te mau rave'a haaparareraa parau-ti'a Tuʻaʻa te mau tauiraa i raro a'e i te 0.01mm. Te faaauraa i te reira i ni'a i te hoho'a i ni'a i te hoho'a tahito, vai 3% Te faito o te mau hape—te faaiti nei te faito hape i te faito hape matamua e tae roa ' tu i raro 0.3% mai te haamataraa.

Hau atu â: te hō'ē Tā'ata'a ua faanahohia te reira e te mau robot, e te faatere nei aua mau rima i te mau mauhaa. Te faataa ra te reira i te fifi o te puai o te ore e itehia mai roto mai i te putuputuraa a te rima—e ite oe, te mea e ere i te mea ino roa—e te reira ïa te huru o ta tatou i tâpû i nia i te mau taheraa toto.

E ere te automa i ô nei i te mea, e'ere. The workshop’s system watches real-time data from every machine. If an injection molding machine’s temperature changes more than ±2℃, the system shuts down right away and alerts the team. Technical staff can arrive at the site in a short time and solve the problem. so we don’t end up making big batches of bad products.

We make 80,000 trigger sprays a day with these automated lines, and they only make about 240 defective ones each day. A traditional factory they might have up to 10,000 bad ones daily. Just this one difference saves clients tens of thousands of dollars a year on reworking or throwing away bad products.

2.Full-Process Quality Control: Ua haapii mai te “Multi-Layer Filter” for Stopping Risks

“Not a single unqualified trigger spray leaves the factory”— o te ture ïa no ta tatou pǔpǔ QC. No te faatupu i te reira, Ua patu matou i te hoê “enei'a” no te fana'o i te mau atâtaraa mai te hamaniraa i te mau mea atoa e tae atu i te horoaraa.

hō'ē: E hi'opo'a

E faaohipa tatou i te mau hu'ahu'a e te mau hu'ahu'a atoa ta tatou e faaohipa no te faatupu i te mau hu'ahu'a na roto i te mau hi'opo'araa no te pato'i i te veavea e te paari. Ei hi'oraa, E tia ia mǎhu i te 80°C no te 72 mau hora ti'a—aita e hape, aita.

hō'a: Te mau hoho'a i roto i te hamaniraa

I muri a'e i te putuputuraa, ta matou e maiti 5 e faatupu i te mau hu'ahu'a 200 no te mau hi'opo'araa teitei. Ua tuu matou i te reira i raro a'e i te 1.2MPa no te 30 miniti. Mai te mea e, te vai ra atoa te tahi taheraa pape, Ua ta'i matou i te taato'araa o te pŭpŭ. E tapea teie taahiraa i te faito o te taheraa toto i raro a'e i te 0,1%—e iti a'e i te faito au noa o te ohipa hamaniraa tauihaa 1%.

Te toru o te ahu mā: 100% hopea hou a topa ' i te pahi

E farii te mau mea atoa i te hoê hi'opo'araa no ni'a i te huru o te pape e te hi'opo'araa i te mau hoho'a hou a faaohipa ' i. Te mau mea atoa e faatupu i te hoê hape i nia i te faito ±5% o te faataahia mai te hape, e ua ite atoa matou i te mau hoho'a e te mau auri. Mauruuru no teie na ahu e toru, e 99,9% te faito o te haereraa i mua no te faatupu i te mau fifi, o te faaite ra e mea iti a'e te mau amuamu no roto mai i te mau fifi i te pae no te faatupu i te mau fifi.

3.Te hoê rave'a no te faaho'i-faahou-raa mai i te mau mea: Ua haapii mai te “Backbone” no te mau rave'a aravihi no te aravihi

Ia ma'iti ana'e te feia e farii ra i te mau rave'a no te faatupu i te mau hu'ahu'a, E pinepine ratou i te haapeapea: “E hinaaro te huru maitai, e mea faufaa roa râ no te mau tao'a tahi?” Ua patuhia ta tatou faanahoraa hamaniraa no te tata'i i te haape'ape'araa.

I teie nei, E rave rahi ta tatou mau reni spy. No te mau hi'oraa, Ua naeahia te 80,000 i te mau mahana atoa 300 hoê matahiti hoê matahiti te maoro i te ohipa hoê matahiti, o te reira 24 Te mau hu'ahu'a i te matahiti hoê. hau atu i te navai no te faatere i te mau faaueraa rahi a te feia hoo.

No te mau hu'ahu'a, E nehenehe ta tatou mau reni hamaniraa tauihaa e taui oioi. Mai te hoê faanahoraa matauhia no te haamata i te hamaniraa i te hoê faanahoraa, E nehenehe ta tatou e faaoti i te mau rave'a hamaniraa tauihaa 24 E hora—e te vai ra te reira 50% vitiviti a'e i te faito au noa o te ohipa tapihooraa.

E i ô nei te taviri: Aita roa ' tu tatou e hoo nei i te hoê huru. E mau rave ohipa QC ta'na iho i ni'a i te mau reni atoa. I te mau pu'e rarahi, ia horo ana'e te mau reni i te vitiviti rahi, Aita roa'tu matou i tapa'o i te taime QC. E vai noa te mau titauraa,E ti'a i te mau hu'ahu'a atoa ia faaî i ta tatou fare inuraa teitei.

Ia haere ana'e outou na roto i ta matou fare hamaniraa tauihaa, te mau ravea apî, Hi'opo'a-maite-raa i te mau mea, e te aravihi no te hamani i te mau mea. A tuu i te reira i roto i te hoê mea, no te haapapû e, ua noaa ia outou te mau hu'ahu'a. Ua ite matou paatoa e e nehenehe te hoê hu'ahu'a iti e faaohipahia no te faaineine i ta outou reni hamaniraa, ua faaino i to outou huru i te pae hopea, e tae noa ' tu to outou tapao. No teie tumu no te aha ratou no teie tumu no te aha no nia i te tumu o te tumu., E hi'opo'a-maite-hia ta tatou mau tao'a no te faaiti i te faito o te hape i ni'a i te faito iti roa a'e e no te horo'a i te mau tao'a maitai roa i te feia hoo. E ere te riroraa ia tatou ei mea maitai roa. E maiti te reira i te tapea i te mau atâtaraa huna, e te raveraa i te hoê ohipa aravihi no te hoo mai i te moni no te hoê tau maoro.