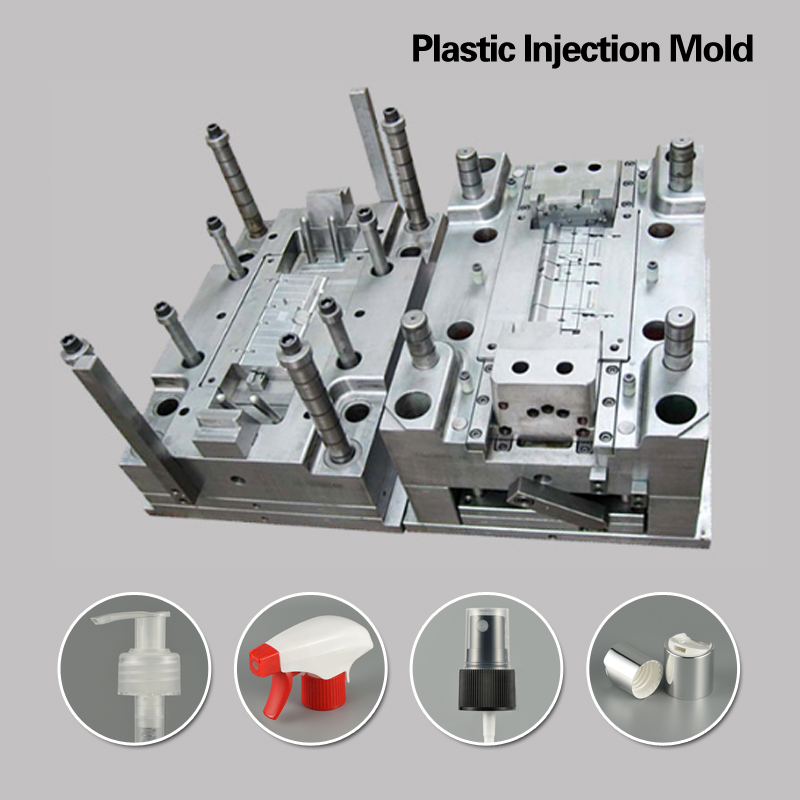

Injection molds can produce a variety of products

Personal care products: Injection molds can be used to produce items such as shampoo bottles, soap dispensers, and lotion pumps.

Cleaning products: Injection molds can be used to manufacture spray bottles, trigger sprayers, and other types of cleaning product containers.

Cosmetics packaging: Injection molds can be used to make mascara tubes, lipstick cases, and other types of cosmetic packaging.

Fragrance packaging: Injection molds can be used to produce perfume bottles, atomizers, and other fragrance packaging components.

Umuman, injection molding is a widely used manufacturing process in the daily chemical industry, as it allows for high-volume production of high-quality, consistent products.

Injection mold production process

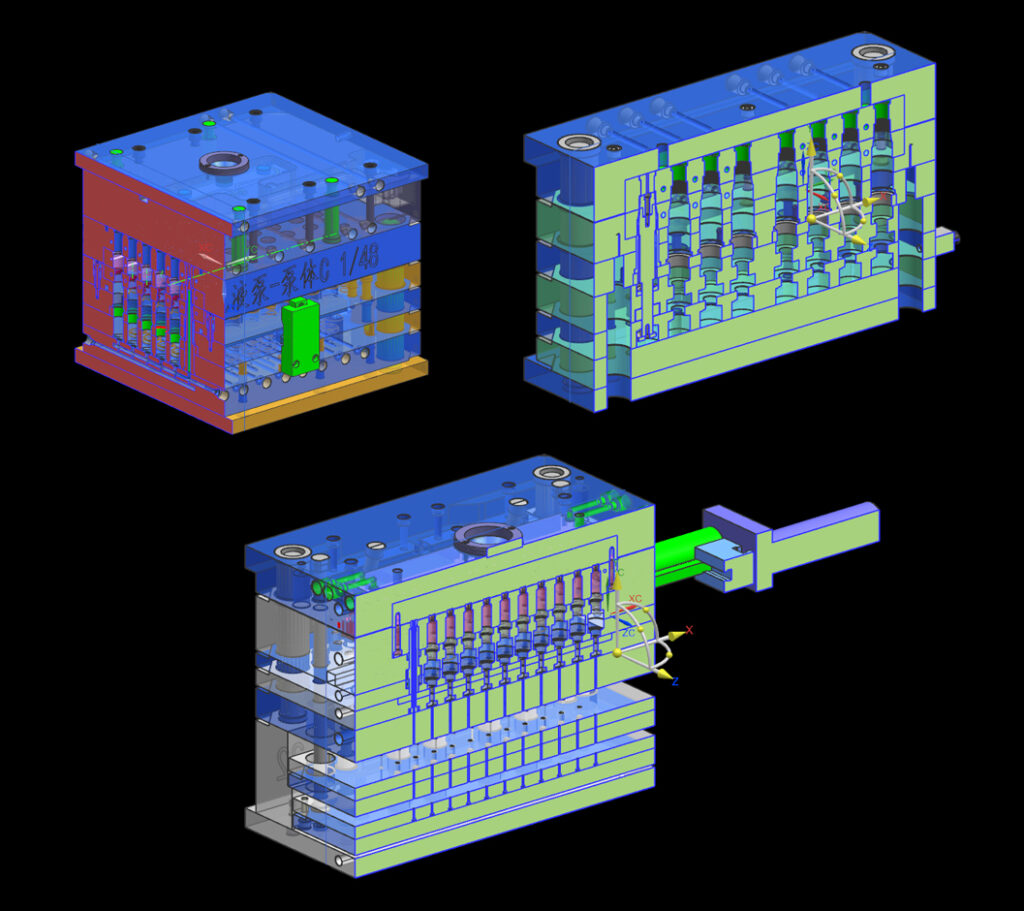

Step 1: Designing the Mold

The first step in producing an injection mold is to design the mold using computer-aided design (CAD) software. The mold designer will create a 3D model of the part to be produced, taking into consideration factors such as wall thickness, gate location, and material flow. The mold designer will also determine the size and shape of the mold, the number of cavities (the number of parts the mold can produce at once), and any additional features such as cooling channels.

Step 2: Creating a Prototype

Before the final mold is produced, a prototype is created to test the design and make any necessary adjustments. The prototype can be created using a variety of techniques, such as 3D printing or CNC machining. Once the prototype is tested and approved, the mold designer can move on to the next step.

Step 3: Producing the Mold

The mold is created by machining the mold cavities and cores from a block of metal, usually aluminum or steel. This process can be done using CNC machines or other types of machining equipment. The mold is then polished and finished to ensure that the plastic parts produced by the mold are of high quality.

Step 4: Adding Components

After the mold is machined and finished, components such as ejector pins, sprue bushings, and guide pins are added to the mold. These components help to control the injection molding process and ensure that the plastic parts are produced correctly.

Step 5: Testing the Mold

Once the mold is complete, it is tested to ensure that it is working correctly. This involves injecting molten plastic into the mold and producing a test part. The test part is then examined to ensure that it meets the design specifications and quality standards.

Step 6: Mass Production

After the mold has been tested and approved, it can be used for mass production. The mold is installed in an injection molding machine, and the machine is set up to produce the desired number of parts. The plastic is injected into the mold cavities, and the finished parts are ejected from the mold.

Yakunida, the production of injection molds is a complex and precise process that requires careful planning and attention to detail. The mold designer must create a design that takes into account all of the factors that will affect the final part, and the mold itself must be machined to exact specifications. Biroq, with the right design and production process, injection molds can produce high-quality plastic parts efficiently and cost-effectively.