In daily chemicals, cleaning, and many other fields, foam pumps are products that enable liquids to generate foam. Choosing the right foam pump not only enhances the user experience of your product but also extends its lifespan and reduces maintenance costs.

I. Understanding How Foam Pumps Work

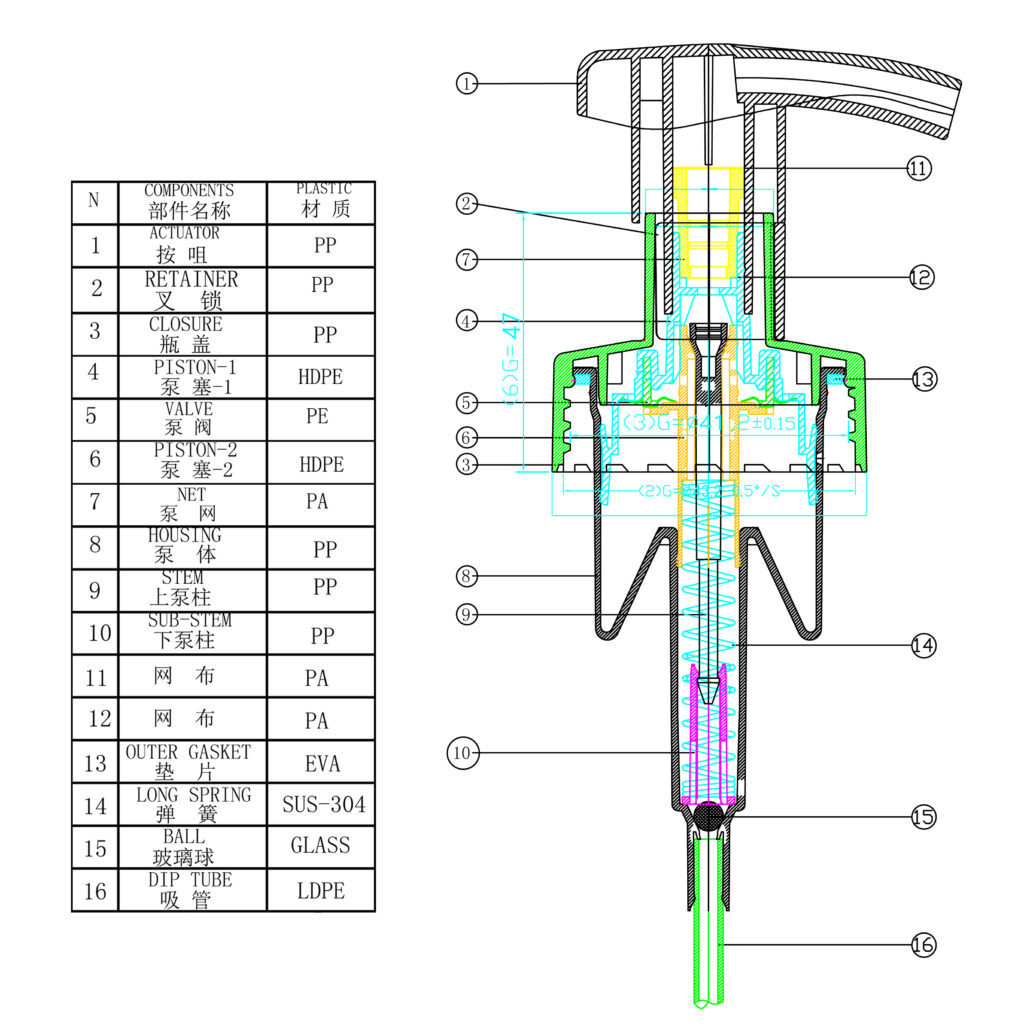

When pressing the pump head, the piston moves down, compressing the spring. The one-way valve is in a closed state, and the liquid moves up through the outlet, passing through the filter screen. The liquid containing surfactants mixes with air to form foam and is discharged through the pump nozzle.

When releasing the pump head, the spring pushes the piston up, creating negative pressure in the pump body. The one-way valve opens, and liquid enters the pump body.

II. Product Features and Key Points

- The foam pump contains two filter screens (welded by ultrasonic welding). When liquid passes through the filter screens, it transforms into foam.

- The difference from lotion pumps is the presence of 2 filter screens, which produce foam output.

- Note that damaged filter screens will result in poor foam production or no foam at all.

III. Key Parameters for Selecting Foam Pumps

1.Output Volume and Foam Fineness

Hand soap foam pumps typically have an output volume of 0.8±0.1cc, while cleaning agent foam pumps may require larger output volumes.

The fineness of foam directly affects user experience. Fine, stable foam can better cover cleaning surfaces and improve cleaning efficiency.

2.Material and Corrosion Resistance

The material used in foam pumps should be chosen based on the qualities of the liquid. Neutral cleansers, mildly acidic or weakly alkaline solutions are all examples of common liquids. Choose corrosion-resistant materials for extremely corrosive liquids, such as PP, PE, PET plastics, or stainless steel.

3.Installation Method and Size

Foam pumps are commonly installed using threaded or snap-on methods. Depending on the mouth design of the packing bottle, select the suitable installation method. Consider the compatibility between the pump body size and the packaging bottle to guarantee a secure installation and easy operation.

IV. Choosing the Right Foam Pump Based on Application Scenarios

1.Daily Chemical Cleaning Products

For hand soap, isicoci sobuso, body wash, njl., it’s recommended to choose foam pumps with fine foam and moderate output volume to enhance user experience. Umzekelo, the I-SM-FP-05L Green Foam Pump features a stylish appearance with fine and rich foam, making it perfect for high-end daily chemical products.

2.Household Cleaning Products

For kitchen cleaners, bathroom cleaners, njl., it’s recommended to choose foam pumps with larger output volumes and strong corrosion resistance to meet high-efficiency cleaning needs. The I-SM-FP-08 White Foam Pump is manufactured with high-quality materials, offers strong corrosion resistance, and is suitable for various household cleaning products.

V. Choosing a Reliable Foam Pump Manufacturer

Selecting a manufacturer with strong capabilities and good reputation is key to ensuring product quality and after-sales service. Here are factors to consider when choosing a manufacturer:

- Check for independent design capabilities and advanced production equipment.

- Verify ISO and other quality certifications.

- Ensure after-sales service meets standards, including technical support, maintenance, and parts supply.

Choosing the appropriate foam pump necessitates careful evaluation of product usage scenarios, flow needs, material requirements, and manufacturer capabilities and services. Songmile Packaging provides foam pumps in a variety of sizes and shapes to satisfy the needs of diverse industries and consumers.

If you’re looking for high-quality, reliable foam pump products, please visit our website https://www.songmile.com/product-category/foam-pumps/ for more details, or contact our sales team for professional selection advice.