An assembly machine for plastic trigger sprayers normally comprises of numerous stations that each execute a distinct task during the assembling process. Here’s an overview of how such a machine operates:

Plastics molding: The primary components of the trigger sprayer, such as the container, 觸發, and nozzle, are created first using plastic injection or blow molding. These components are manufactured in big quantities and supplied into the assembly machine.

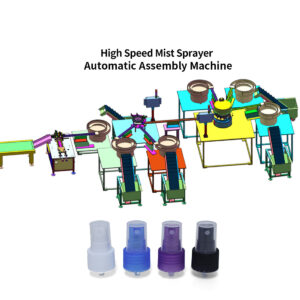

Molded components are automatically supplied into the assembly machine using vibratory bowl feeders, conveyors, or robotic pick-and-place systems. These guarantee that the components are appropriately positioned before assembly.

Assembly stations: The assembly machine has several stations where components are brought together and assembled. These stations can include: 一個. Bottle loading: Plastic bottles are transferred to a conveyor or fixture. b. Trigger insertion: Insert the trigger mechanism into the bottle’s neck and secure it. c. Nozzle assembly: The nozzle components, including the swirl chamber, nozzle cap, and gaskets, are fitted to the trigger mechanism. d. Crimping/staking: The trigger mechanism is crimped or staked to the bottle neck to create a secure and leak-proof connection. e. Additional components: Depending on the design, dip tubes, filters, or overcaps may be added at different stations.

Quality inspection: After assembly, the finished trigger sprayers may pass through quality inspection stations, such as leak testing, dimensional checks, or visual inspections, to ensure they fit the standards.

Unloading and packaging: Once built and inspected, the trigger sprayers are removed from the machine and packaged for shipment or further processing, such as filling with the necessary liquid.

成個裝配過程高度自動化, 帶機械臂, 傳送帶, 同精密嘅工位協同工作,以確保高效和一致嘅裝配. 該機器旨在處理大量生產,同時保持質量並最大限度咁減對體力勞動的需求.