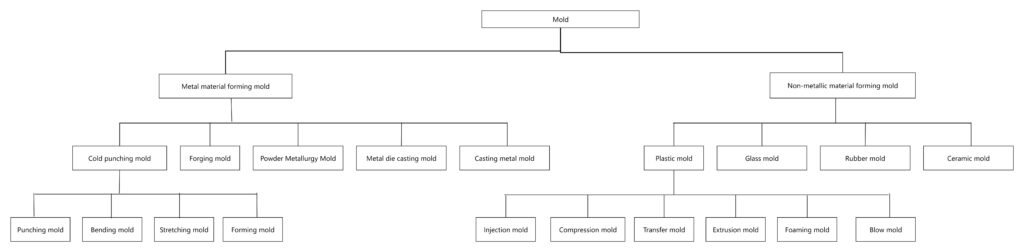

Mold Definition

A mold is a specialized tool for forming product parts and is a major process equipment in industrial production.

According to the Dictionary of Mechanical Manufacturing Processes, a mold is a device that controls the shape and size of the production object.

Molds are used with forming equipment for metal parts such as stamping, forging, 擠壓, and casting, or with forming equipment for non-metallic parts such as plastics, rubber, and ceramics. They can create a wide variety of metal and non-metallic parts. It has become an important processing method in modern industrial production.

Parts formed by molds are usually called “workpieces” (such as stamped parts, forged parts, plastic products, castings, 等。).

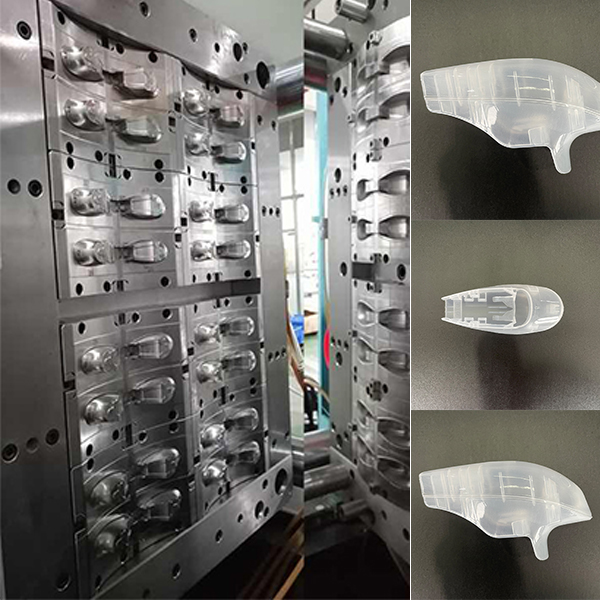

Molds and Products

麻麻, the production of packaging materials starts from the procurement of raw materials, and through the cooperation of molds and equipment, the products are formed. 然之後, after surface treatment and decoration, the finished products are completed. 其中, the forming process of molds is the focus of this process.

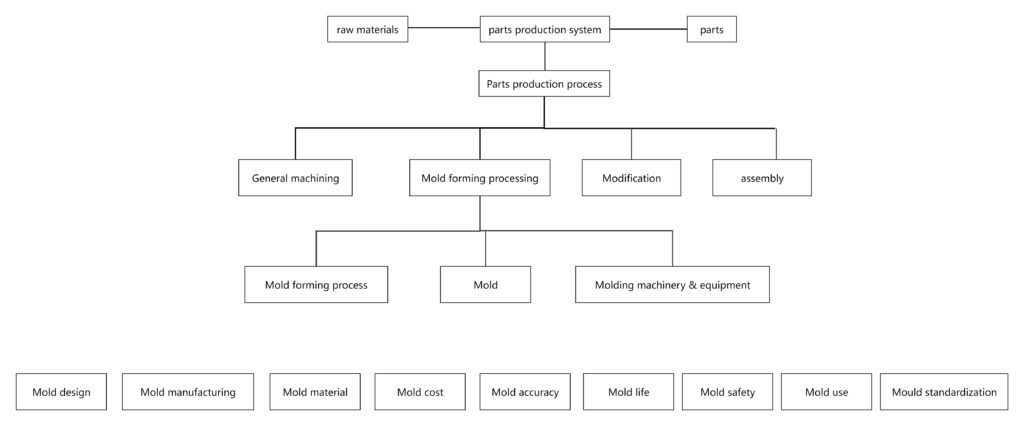

Mold Classification

Molds can be classified based on the different materials of the products they are used to manufacture, and the materials of the molds themselves are also diverse. They are mainly customized according to the products. Different materials and processes directly determine the cost of the molds.

According to the materials being formed, molds can be divided into metal molds and non-metal molds. Metal molds can be further classified into casting molds (for non-ferrous metal die-casting and steel casting) and forging molds, 等. Non-metal molds can be divided into plastic molds and inorganic non-metal molds. And based on the different materials of the molds themselves, they can be classified as sand molds, metal molds, vacuum molds, wax molds, 等.

其中, with the rapid development of high-molecular plastics, plastic molds are closely related to people’s lives.

Plastic molds can generally be classified as injection molding molds, extrusion molding molds, gas-assisted molding molds, 等.

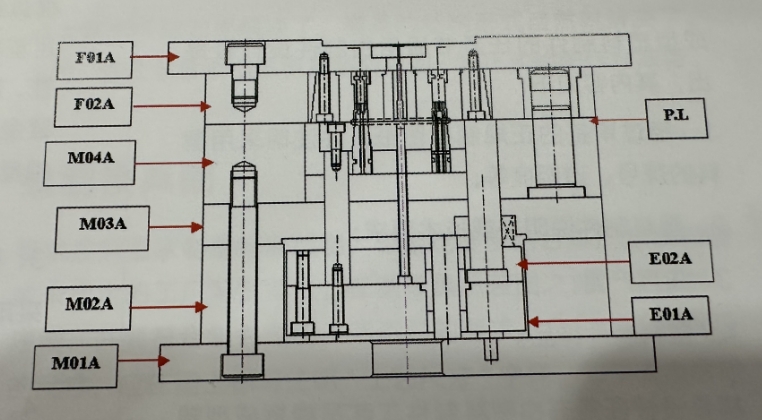

Mold Manufacturing Process

第一, to make a mold, there must be a design. You need to take the ideas in your mind and turn them into a design. This is where prototypes come in. Prototypes transform your imagination into a tangible object. You can make it more perfect according to your vision. Once the prototype is done, it is sent to a professional mold factory. The factory then sends it to a scanning company to scan the dimensions. These are the primary data for making the mold. Only with these data can a replica of the prototype be made. After the scanning is done, the mold design engineer uses professional software such as AutoCAD and Pro/E to design it. 同時, other tasks are also carried out, such as selecting steel blanks for the mold.

After the steel is selected, it is just a pile of iron and not a mold. It needs to be processed to become a mold. When the steel is purchased, it cannot be processed randomly. It needs to be processed precisely, and the higher the precision, the better. Currently, the most advanced technology can produce molds with an error of just a few microns. 然而, such molds are expensive. They require high-quality steel and advanced machines, which often cost over a million. 答案係肯定嘅, without skilled workers, it’s all in vain.

Secondly, after selecting the steel, the work begins. Skilled workers process each part of the mold according to the drawings using various machines (such as lathes, planers, milling machines, grinders, electrical discharge machines, wire cutters, and CNC machining centers). 然之後, the parts are assembled and debugged.

For molds with simple cavities and cores, a CNC programmer writes the program and uses a CNC machine to process the mold. For areas that cannot be processed by the CNC machine, an electrical discharge machine is used for processing. For molds with complex curved surfaces, a three-axis CNC machine is used for processing. The NC program is generated based on the 3D model in professional CAM software.

最後, after the mold is completed, it is sent for trial molding. Once the trial molding is successful, the mold can be released.

| F01A | Upper Fixing Plate | E02B | Pipe Jacking | E01A | Lower Ejector Plate |

| F02A | Master Template | E02C | Return Pin | E02A | Upper Ejector Plate |

| M01A | Lower Fixing Plate | P01A | Feed Connector | F | Master Mold |

| M02A | Standing Plate | P02A | Locating Ring | M | Male Mold |

| M03A | Auxiliary Plate | P03A | Guide Pillar | P.L | Mold Parting System |

| M04A | Male Grinding Plate | P04A | Guide Pin Sleeve |

Mold application

Molds are widely used in the cosmetic packaging materials industry. Plastic products, glass products, and paper products all require molds. The cost of molds directly determines the cost of packaging materials and also the delivery time of packaging materials. 因此, for packaging materials, molds are the core and fundamental.