在每日化學包裝行業, 這 扳機噴霧器 is essential—its functionality dictates how the product is actually used.

End consumers often face the frustration of a sprayer jamming, leaking, or breaking before the bottle of cleaner is even finished. Such a poor experience directly damages a brand’s reputation.

在松米爾, we deeply understand this pain point. That is why we hold our production to rigorous standards: ensuring every Songmile sprayer withstands over 3,000 press-and-rebound cycles.

所以, how exactly does Songmile’s 扳機噴霧器 achieve this level of durability?

1.The Anatomy: Precision in Every Part

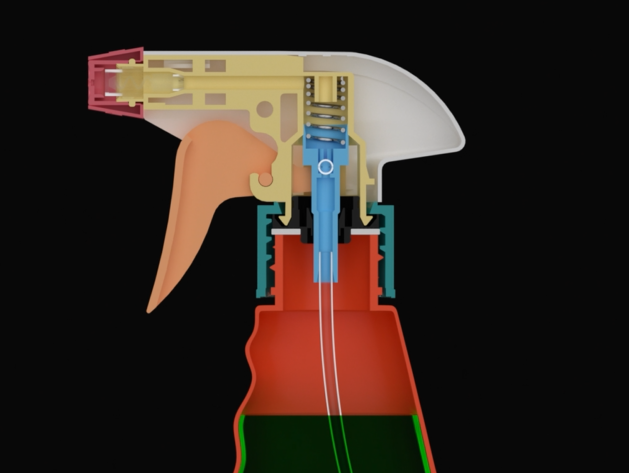

Although a 扳機噴霧器 may look simple on the outside, it is actually an assembly of over ten precision components. To achieve a lifespan of 3,000+ cycles, every single part must function in perfect coordination.

The Piston

This is the core pressure-generating component. If the friction between the piston and the cylinder wall is too high, the pressing action feels stiff; if it is too low, the pressure will be insufficient, resulting in a weak spray. Songmile utilizes high-precision injection molds to control tolerances at the micron level, ensuring the piston remains smooth and perfectly sealed even after thousands of friction cycles.

The Spring

This is the critical component that determines the sprayer’s lifespan. Many inferior sprayers use ordinary steel, which rusts upon contact with liquid or loses resilience after just a few hundred presses. We use high-grade 304 或者 316 stainless steel springs. Not only do they offer superior corrosion resistance, but they also undergo strict tension testing to ensure the rebound force remains as strong as new after 3,000 cycles.

The Glass Ball/Valve

This controls the direction of the liquid flow. If the glass ball lacks perfect sphericity or the valve seat is uneven, it leads to backflow or an inability to draw liquid. Our glass spheres are perfectly round, guaranteeing precise dispensing with every press.

The Gasket

This is the final line of defense against leakage. We employ materials with high elasticity to ensure a tight seal between the sprayer and the bottle neck. This guarantees zero leakage, even under transportation vibrations or when the bottle is inverted.

2.How do we ensure a lifespan of 3000+ cycles?

True 質量控制 stems from our relentless dedication to materials and craftsmanship.

我. Refusing Recycled Materials,Insisting on Virgin Material

The toughness of the plastic has a direct impact on the product’s longevity. To save money, several sprayers on the market contain a high percentage of recycled material. This causes the plastic to become brittle and susceptible to breaking during use, particularly near the trigger connection point. We insist on using 100% virgin PP material for important stress-bearing components, ensuring that the structural strength is sufficient to withstand high frequency use.

ii. Precision Mold Maintenance

The mold is the “mother” of the product. Because all of our sprayer components are manufactured using injection molding, any roughness on the mold surface results in parts with “burrs” (rough edges), which can lead to leakage or jamming. We diligently follow regular mold maintenance and polishing procedures to ensure that every accessory produced is smooth, precise, and faultless.

iii. Rigorous Laboratory Testing

- Automatic Fatigue Tester: Simulates high-frequency manual pressing over thousands of continuous cycles to observe for any jamming, breakage, or spring failure.

- Vacuum Leak Tester: We utilize multiple vacuum chambers to simulate various pressure scenarios, strictly verifying the sealing performance.

- Spray Pattern Testing: Ensures that the spray performance of the mass-produced goods delivered to you is perfectly consistent with the approved samples.

3.Why Durability Matters for Your Brand

中外近代史發展的比較也體現在飲水機的發展上 2025 and beyond, the packaging market will turn toward sustainability 和 reusable systems.

Consumers are increasingly purchasing “Refill Packs” and recycling their original spray bottles. This adjustment throws a significant pressure on the 扳機噴霧器. A sprayer must now last for two, three, or four refills, not simply one bottle of liquid.

By choosing Songmile’s high-durability sprayers, you are:

- Supporting the Refill Economy:Enabling your clients to reuse your packaging with confidence.

- Protecting Brand Loyalty:Providing a quality experience every time a customer uses your product.

- Reducing Waste:A long-lasting sprayer results in fewer broken plastic parts ending up in landfills.

一個 扳機噴霧器 is a little device that requires extensive engineering. It combines material science, mold precision, and fluid dynamics.

Songmile manufactures consistency rather than merely plastic bits.

Are you ready to improve your packaging reliability? Contact us immediately to acquire a sample kit and experience the “Songmile Smoothness” for yourself.