Definición de molde

Un molde es una herramienta especializada para formar piezas del producto y es un equipo de proceso importante en la producción industrial..

Según el diccionario de procesos de fabricación mecánica, Un molde es un dispositivo que controla la forma y el tamaño del objeto de producción.

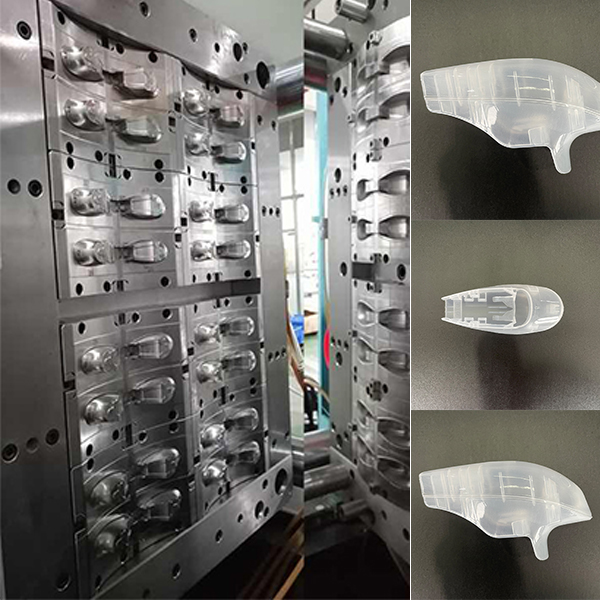

Los moldes se utilizan con equipos de formación para piezas de metal como el estampado, forja, extrusión, y casting, o con el equipo de formación para piezas no metálicas como plásticos, goma, y cerámica. Pueden crear una amplia variedad de piezas metálicas y no metálicas.. Se ha convertido en un importante método de procesamiento en la producción industrial moderna..

Las piezas formadas por moldes generalmente se llaman “piezas de trabajo” (como piezas estampadas, piezas forjadas, productos de plástico, piñones, etc.).

Moldes y productos

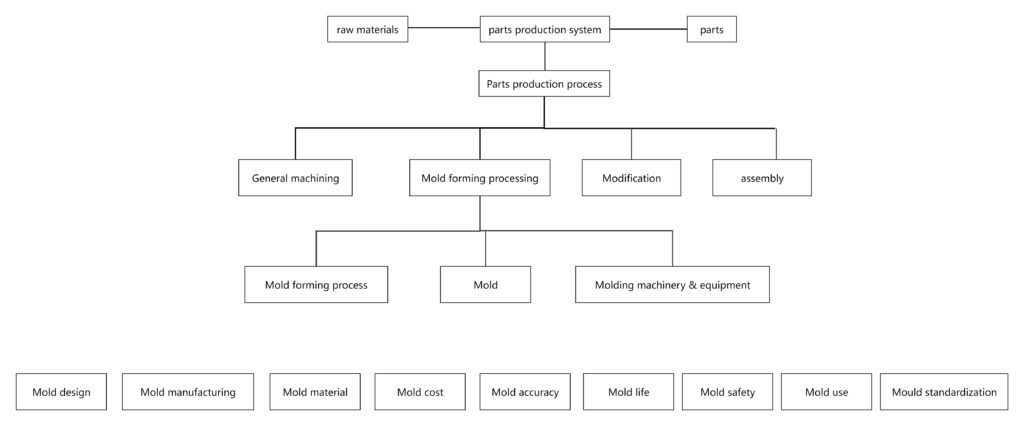

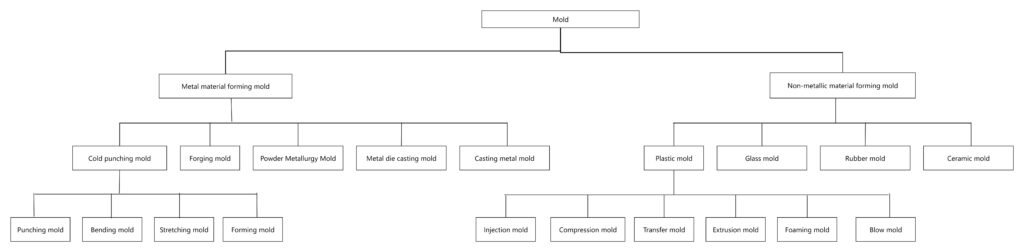

Generalmente, La producción de materiales de embalaje comienza desde la adquisición de materias primas, y a través de la cooperación de mohos y equipos, Los productos se forman. Entonces, Después del tratamiento y decoración de la superficie, Los productos terminados se completan. Entre ellos, El proceso de formación de moldes es el foco de este proceso..

Clasificación de moho

Los moldes se pueden clasificar en función de los diferentes materiales de los productos que se utilizan para fabricar, y los materiales de los moldes también son diversos. Se personalizan principalmente de acuerdo con los productos.. Diferentes materiales y procesos determinan directamente el costo de los moldes..

De acuerdo con los materiales que se están formando, Los moldes se pueden dividir en moldes de metal y moldes no metálicos. Los moldes de metal se pueden clasificar aún más en moldes de fundición (para fundición a died de metal no ferroso y fundición de acero) y forjando moldes, etc.. Los moldes no metálicos se pueden dividir en moldes de plástico y moldes no metálicos inorgánicos. Y basado en los diferentes materiales de los propios moldes, se pueden clasificar como moldes de arena, moldes de metal, moldes de aspiración, moldes de cera, etc..

Entre ellos, con el rápido desarrollo de plásticos de alto molecular, Los moldes de plástico están estrechamente relacionados con la vida de las personas.

Los moldes de plástico generalmente se pueden clasificar como moldes de moldeo por inyección, Moldes de moldura de extrusión, moldes de moldeo asistido por gas, etc..

Proceso de fabricación de moho

Primero, Para hacer un molde, Debe haber un diseño. Necesitas tomar las ideas en tu mente y convertirlas en un diseño.. Aquí es donde entran los prototipos. Los prototipos transforman su imaginación en un objeto tangible. Puedes hacerlo más perfecto según tu visión. Una vez que se realiza el prototipo, se envía a una fábrica de moho profesional. La fábrica lo envía a una empresa de escaneo para escanear las dimensiones. Estos son los datos principales para hacer el molde. Solo con estos datos se puede hacer una réplica del prototipo. Después de que se realice el escaneo, El ingeniero de diseño de moho utiliza software profesional como AutoCAD y Pro/E para diseñarlo. Al mismo tiempo, También se llevan a cabo otras tareas, como seleccionar espacios en blanco de acero para el molde.

Después de que se seleccione el acero, Es solo un montón de hierro y no un molde. Necesita ser procesado para convertirse en un molde. Cuando se compra el acero, No se puede procesar al azar. Necesita ser procesado con precisión, y cuanto mayor sea la precisión, Cuanto mejor. Actualmente, La tecnología más avanzada puede producir moldes con un error de unos pocos micras. Sin embargo, Tales moldes son caros. Requieren acero de alta calidad y máquinas avanzadas, que a menudo cuesta más de un millón. Por supuesto, sin trabajadores calificados, Todo es en vano.

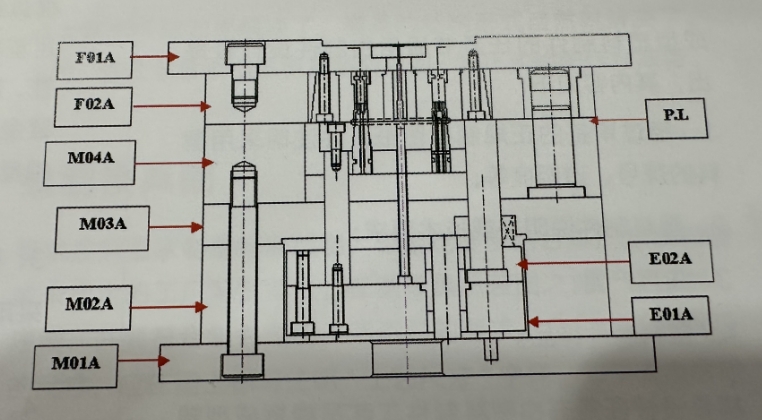

En segundo lugar, Después de seleccionar el acero, El trabajo comienza. Los trabajadores calificados procesan cada parte del molde de acuerdo con los dibujos utilizando varias máquinas (tales como temas, departamento, máquinas de fresado, muelas, máquinas de descarga eléctrica, cortadores de alambre, y centros de mecanizado CNC). Entonces, Las piezas se ensamblan y depuran.

Para moldes con cavidades y núcleos simples, Un programador de CNC escribe el programa y utiliza una máquina CNC para procesar el molde. Para áreas que la máquina CNC no puede procesar, Se utiliza una máquina de descarga eléctrica para procesar. Para moldes con superficies curvas complejas, Se utiliza una máquina CNC de tres ejes para procesar. El programa NC se genera en función del modelo 3D en el software CAM profesional.

Finalmente, Después de completar el molde, se envía para moldeo de prueba. Una vez que el moldeo de prueba es exitoso, El molde se puede liberar.

| F01A | Placa de fijación superior | E02B | Chaqueta de tuberías | E01A | Placa de eyector inferior |

| F02A | Plantilla maestra | E02C | Pin de retorno | O02A | Placa de eyector superior |

| M01A | Placa de fijación más baja | P01A | Conector de alimentación | F | Moho maestro |

| M02AAA | Plato de pie | P02A | Anillo de ubicación | METRO | Moho |

| M03A | Placa auxiliar | P03A | Pilar de guía | P.l | Sistema de separación de moho |

| M04a | Plato de molienda | P04A | Manga de pasador de guía |

Aplicación de moho

Los moldes se utilizan ampliamente en la industria de materiales de envasado cosmético. Productos de plástico, productos de vidrio, y los productos de papel requieren moldes. El costo de los moldes determina directamente el costo de los materiales de embalaje y también el tiempo de entrega de los materiales de envasado. Por lo tanto, Para materiales de embalaje, los moldes son el núcleo y fundamental.