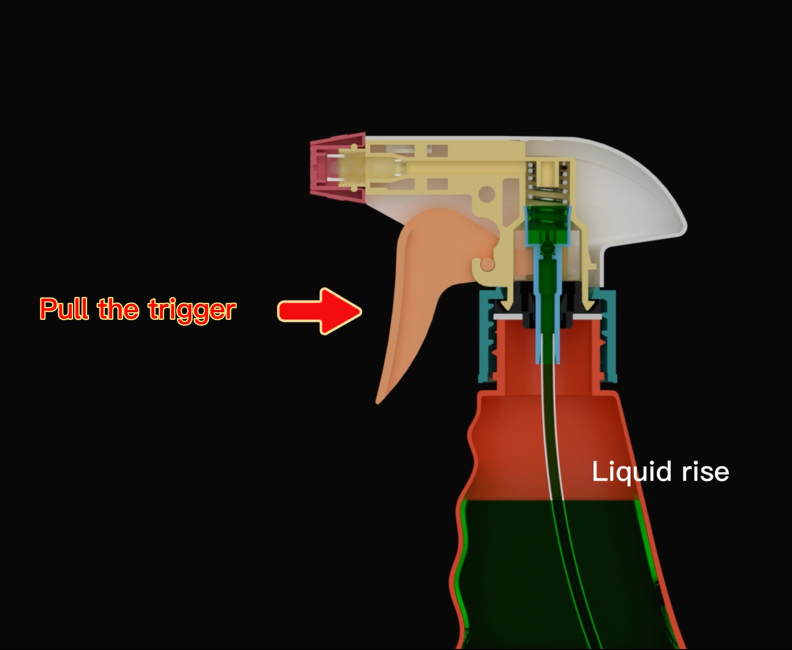

The components of a trigger sprayer typically include:

- Trigger head or handle: This is the part that you hold and press to activate the sprayer.

- Nozzle: This is the part that releases the liquid in a spray that can be adjusted from a fine mist to a steady stream.

- Dip tube: This is a long plastic tube that reaches down into the container and draws the liquid up into the sprayer.

- Filter: This is a small mesh screen that filters out debris and prevents clogging.

- Gasket: This is a rubber or plastic seal that prevents leaks between the trigger head and the bottle.

- Bottle adapter: This is the part that attaches to the opening of the bottle or container.

- Spring: This is a small spring that returns the trigger to its original position after each use.

- Piston: This is a small plastic piece that moves up and down inside the sprayer to compress the liquid and force it out of the nozzle.